Many different kinds of grinding mills exist, including ball mills, hammermills, jaw crushers and roll crushers. A ball mill is a cylinder partially filled with a grinding medium, like small stainless steel balls. When rotated on its axis, the material that fills the rest of the cylinder is crushed. Hammermills instead use hammers to crush material. Read More…

Here at Granutech-Saturn Systems we manufacture high performance equipment which can handle the toughest projects. Our Saturn Hammermills are engineered to meet the specific requirements of a variety of applications.

At Williams Patent Crusher & Pulverizer Co., we are industry leaders in the design and manufacture of high-performance pulverizers that set the standard for reliability, efficiency, and innovation. Since our establishment, we have remained committed to creating cutting-edge solutions that meet the diverse and demanding needs of industries such as mining, power generation, recycling, and more.

We are a trusted partner in delivering innovative size reduction solutions, and at DP Pulverizers Americas Inc., we have built our reputation on precision engineering, consistent quality, and a commitment to advancing material processing technology. Our expertise lies in designing and manufacturing size reduction equipment that meets the demanding needs of industries requiring efficient and...

More Grinding Mill Manufacturers

Jaw crushers, in comparison, crush material between two plates. Roll crushers crush material between two rolls or between a single roll and a fixed, flat plane. Grinding mills serve a wide variety of industries. In gristmills, for example, grinding mills are used to grind grains. Ball mills are commonly used to crush coal in power plants and to make black powder for pyrotechnics. Paint and ceramic materials also are milled in a similar fashion.

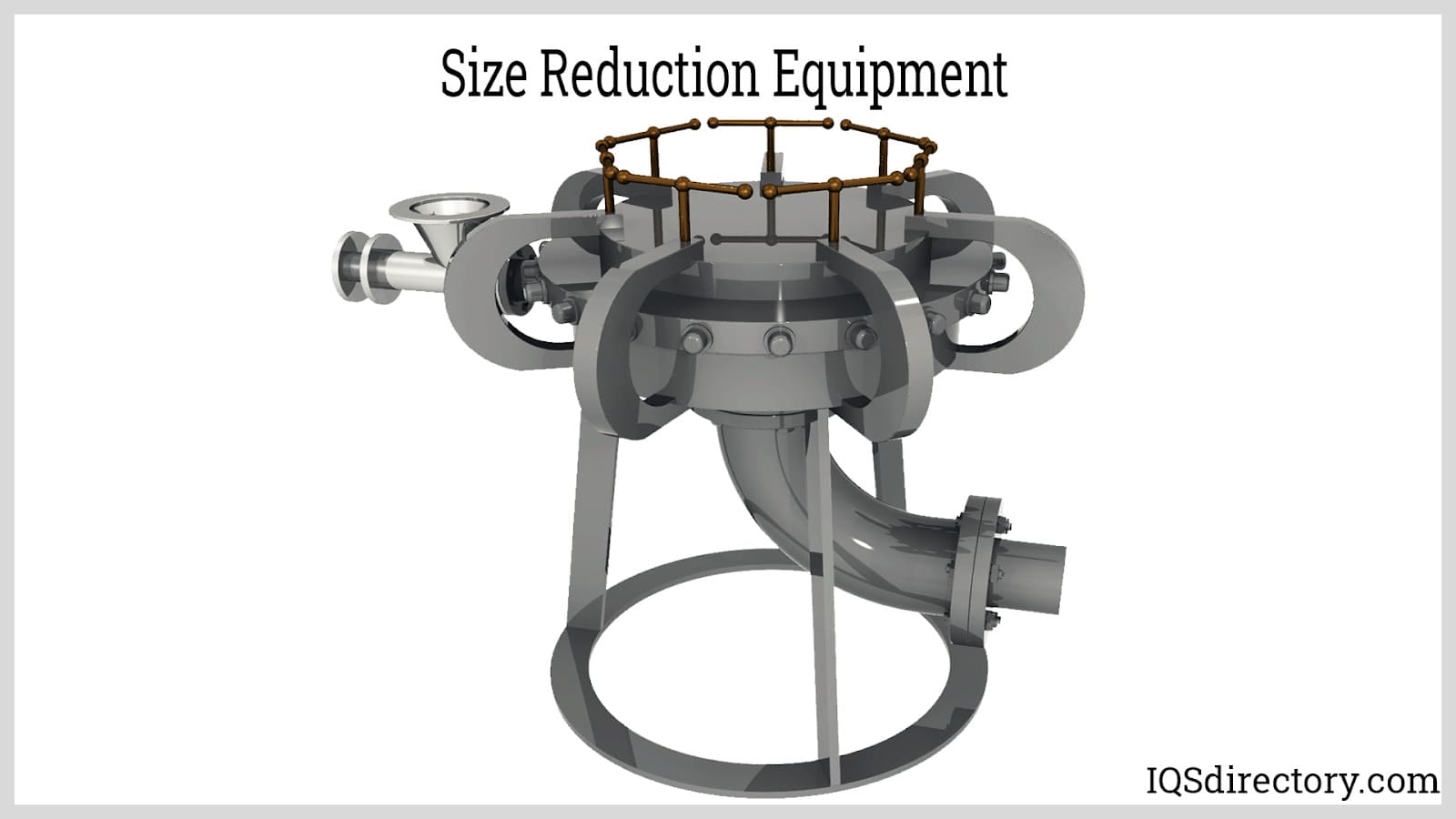

Mills are very important tools for industry and in the development of products for commercial and consumer markets. Size reduction equipment is available in all kinds of configurations for use in many different applications. Jaw crushers, which are used exclusively in industrial processes, are named because of their jaw-like crushing mechanism. The mechanism involves two plates that meet each other at an angle and are positioned vertically.

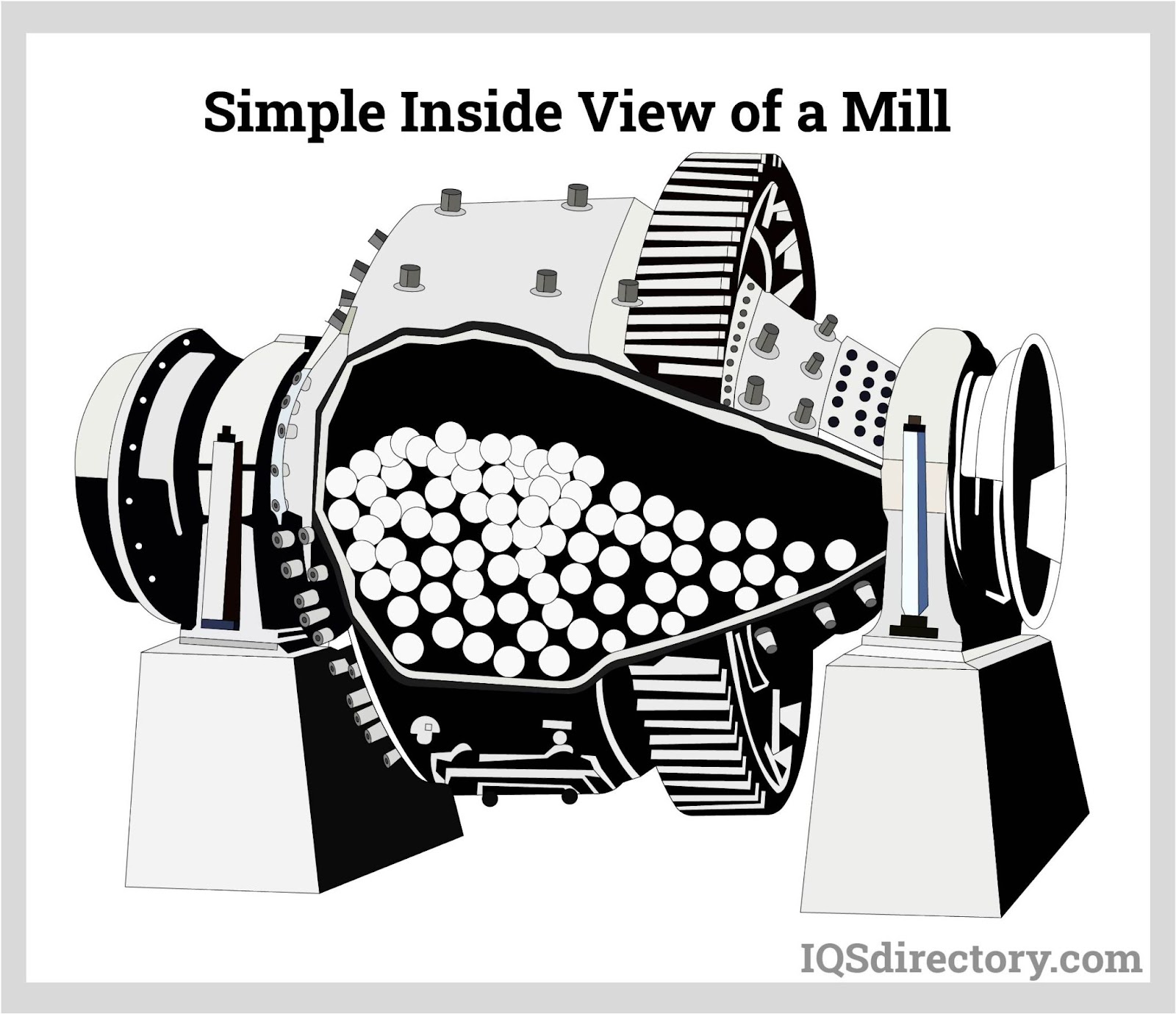

One plate is stationary and the other is moveable, and when the movable jaw moves back and forth, it crushes materials placed between it and the stationary panel. Ball mills hardly resemble jaw crushers at all. They involve a spinning cylinder into which materials to be ground are loaded. The cylinder is also loaded with grinding media, which smash the other materials as the cylinder spins.

ball mills can be small enough to be placed on work benches, and they can be large enough to occupy entire rooms. Hammermills, impactors, impact crushers and every other kind of industrial grinding, crushing and pulverizing equipment vary in terms of their size and capabilities.

Grinding mills are equipment designed to break large quantities of solid material into small pieces. Grinding mills can process an array of materials and can operate through many different methods. In the past, windmills, waterwheels and animals powered grinding mills, but the grinding mills on which industry relies today are much more powerful and are capable of performing much more demanding tasks.

Many different kinds of grinding mills exist, including ball mills, hammermills, jaw crushers and roll crushers. A ball mill is a cylinder partially filled with a grinding medium, like small stainless steel balls. When rotated on its axis, the material that fills the rest of the cylinder is crushed.

Hammermills instead use hammers to crush material. Jaw crushers, in comparison, crush material between two plates. Roll crushers crush material between two rolls or between a single roll and a fixed, flat plane. Grinding mills serve a wide variety of industries. In gristmills, for example, grinding mills are used to grind grains. Ball mills are commonly used to crush coal in power plants and to make black powder for pyrotechnics. Paint and ceramic materials also are milled in a similar fashion.

Mills are very important tools for industry and in the development of products for commercial and consumer markets. Size reduction equipment is available in all kinds of configurations for use in many different applications. Jaw crushers, which are used exclusively in industrial processes, are named because of their jaw-like crushing mechanism.

The mechanism involves two plates that meet each other at an angle and are positioned vertically. One plate is stationary and the other is moveable, and when the movable jaw moves back and forth, it crushes materials placed between it and the stationary panel. Ball mills hardly resemble jaw crushers at all. They involve a spinning cylinder into which materials to be ground are loaded.

The cylinder is also loaded with grinding media, which smash the other materials as the cylinder spins. Ball mills can be small enough to be placed on work benches, and they can be large enough to occupy entire rooms. Hammermills, impactors, impact crushers and every other kind of industrial grinding, crushing and pulverizing equipment vary in terms of their size and capabilities.

Jaw crushers "/>

Jaw crushers "/>

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services