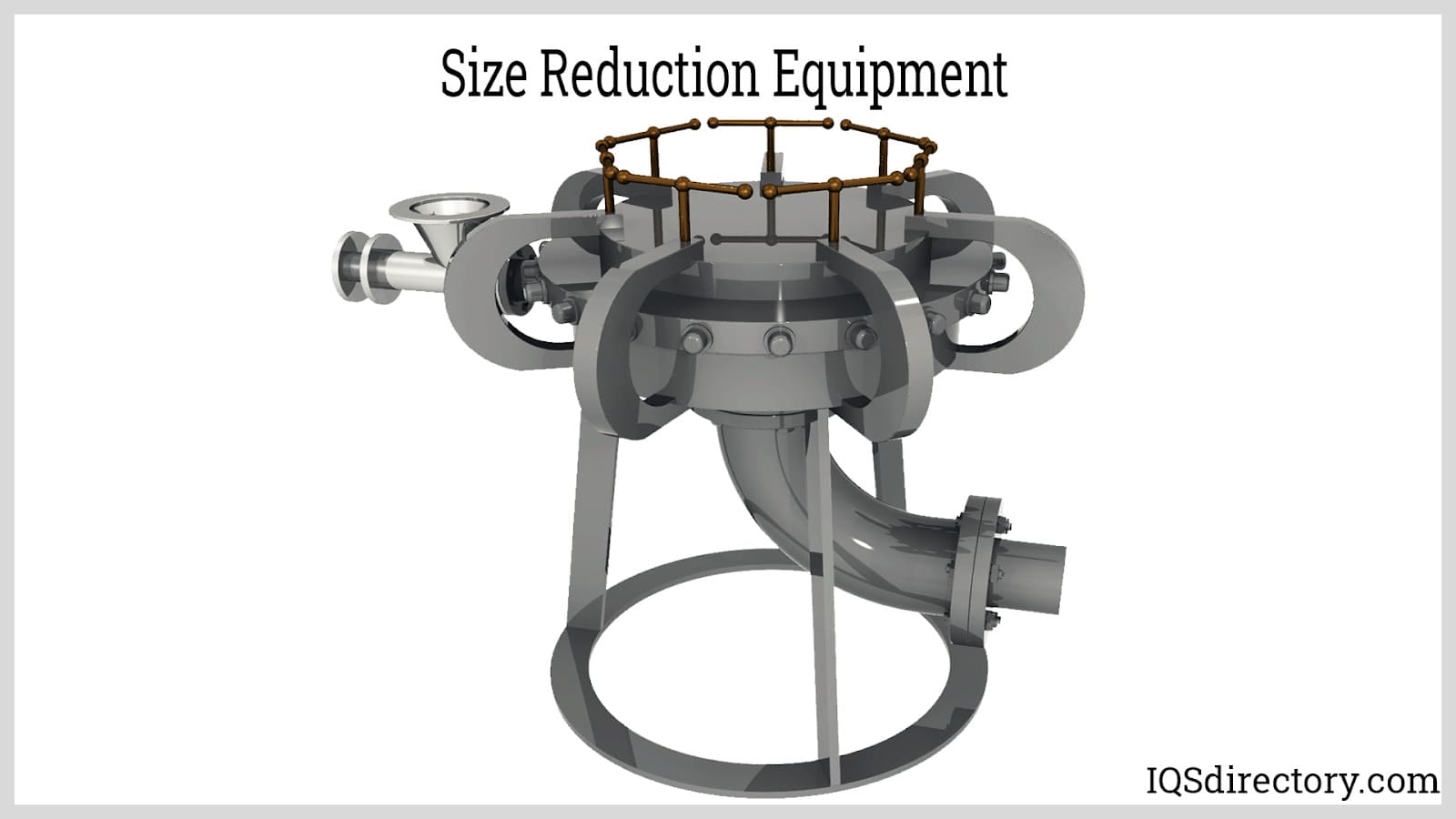

Industrial processes that require jaw crushers and utilize them include the size reduction and disposal of waste products and the refinement of raw mineral materials. Pulverizer manufacturers have responded to the diverse materials reduction needs of industry with a wide variety of pulverizing and crushing equipment. Read More…

Here at Granutech-Saturn Systems we manufacture high performance equipment which can handle the toughest projects. Our Saturn Hammermills are engineered to meet the specific requirements of a variety of applications.

At Williams Patent Crusher & Pulverizer Co., we are industry leaders in the design and manufacture of high-performance pulverizers that set the standard for reliability, efficiency, and innovation. Since our establishment, we have remained committed to creating cutting-edge solutions that meet the diverse and demanding needs of industries such as mining, power generation, recycling, and more.

We are a trusted partner in delivering innovative size reduction solutions, and at DP Pulverizers Americas Inc., we have built our reputation on precision engineering, consistent quality, and a commitment to advancing material processing technology. Our expertise lies in designing and manufacturing size reduction equipment that meets the demanding needs of industries requiring efficient and...

More Jaw Crusher Manufacturers

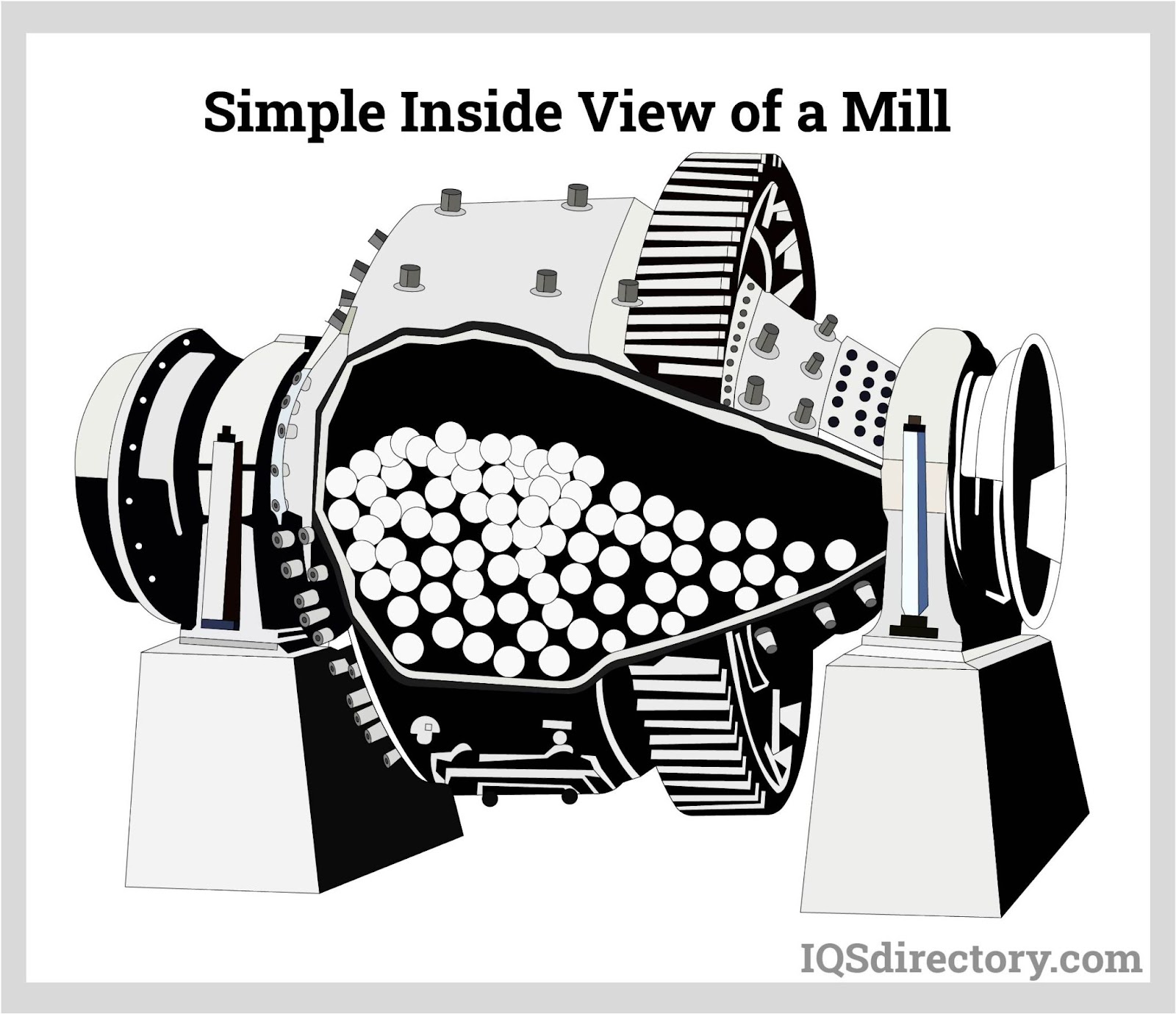

These products range in size and operating capacity from small ball mills to impact crushers that occupy entire rooms. Jaw crushers range in terms of their size and operating capacity, but as a rule they fall somewhere in the middle of the full range of crusher sizes. In some cases they can be made portable, as is the case in some mining jaw crushers. Usually they are about the size of a storage shed.

A jaw crusher functions by the movement of a retractable plate toward and away from a stationary plate. The plates are set at an angle inside of a vertical channel. When material to be crushed is loaded onto the channel, the movable plate moves back and forth, crushing the objects as it moves forward and releasing crushed objects down out of the channel as it retracts.

Because the plates are positioned at an angle, jaw crushing is a multi-phase crushing process. Large materials are partially crushed at the top of the vertical channel, and they move lower as they are broken apart. By its nature, jaw crushing is a somewhat imprecise crushing process and cannot generate the fine-grained crushed objects that other crushing processes can.

For example, hammermills and grinding mills involve turning crushing tools that crush and grind objects over and over until they become small, granulated particles. However, jaw crushing is often not used for processing very small materials. If properly paired with an application, jaw crushing can be a valuable and efficient crushing method.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services