Pulverizers (pulverisers) are mechanical devices used for pulverizing, crushing, and grinding a wide variety of materials to varying finesses. Just some of the many materials that pulverisers can consume include brick, coal, concrete, limestone, paper, plastic materials, metal, rubber, grains, and wood. Read More…

Here at Granutech-Saturn Systems we manufacture high performance equipment which can handle the toughest projects. Our Saturn Hammermills are engineered to meet the specific requirements of a variety of applications.

At Williams Patent Crusher & Pulverizer Co., we are industry leaders in the design and manufacture of high-performance pulverizers that set the standard for reliability, efficiency, and innovation. Since our establishment, we have remained committed to creating cutting-edge solutions that meet the diverse and demanding needs of industries such as mining, power generation, recycling, and more.

We are a trusted partner in delivering innovative size reduction solutions, and at DP Pulverizers Americas Inc., we have built our reputation on precision engineering, consistent quality, and a commitment to advancing material processing technology. Our expertise lies in designing and manufacturing size reduction equipment that meets the demanding needs of industries requiring efficient and...

More Pulverizer Manufacturers

Pulverizers provide essential material size reduction services across a diverse range of industries, supporting applications such as producing fine powders for pharmaceutical formulations, creating pulp for paper manufacturing, grinding grain for food and feed production, shredding and recycling tires, breaking down construction and demolition materials, soil processing, crushing vehicles for scrap recycling, and preparing rock samples for laboratory analysis. Industries that rely heavily on pulverizer machines include construction, agriculture, industrial manufacturing, power generation, pharmaceutical development, landscaping, laboratory research, printing, mining, recycling, and general material processing.

History of Pulverizers

The concept of pulverizing and grinding materials is centuries old, with primitive techniques involving manual hand-grinding stones and mortars. Over time, technological advancements revolutionized material processing. During the Renaissance, hand-held and water-powered hammers were deployed to crush materials, such as coal and minerals. The industrial revolution saw a dramatic rise in energy needs, which spurred the development of early coal grinders to optimize combustion. As chimneys proliferated in residential and industrial settings during the 18th and 19th centuries, demand for pulverized coal soared.

A pivotal moment in pulverizer history arrived in 1824, when French physicist Sadi Carnot designed a thermodynamic engine cycle utilizing pulverized coal, underscoring the value of efficient material reduction in energy production. By the late 19th century, American inventors began expanding the role of pulverizers beyond fuel applications, especially in agriculture. The patent by Loy Satany and Fred Hepworth for a soil pulverizer in 1886, and Frederick Meier’s clod crusher patent in 1892, fueled the agricultural mechanization movement.

The 20th century brought rapid diversification and innovation. The 1940s and 1950s saw engineers increase pulverizer speeds, culminating in the development of the jet pulverizer in 1954. The rise of CNC technology in subsequent decades enabled manufacturers to achieve unprecedented levels of precision, consistency, and programmability in pulverizer design and operation. Today, pulverizers are integral to sustainable construction practices, energy production, recycling initiatives, and advanced material processing. Modern manufacturers continue to innovate, focusing on energy efficiency, environmental sustainability, and the ability to process a wider array of recyclable and advanced composite materials.

How Pulverizers Work

Pulverizers are versatile, high-performance machines engineered for the controlled reduction of solid materials into smaller, more manageable sizes or even powders. They can function in either batch mode—where material is processed in discrete loads—or as part of a continuous, automated production line. Typically, raw materials are delivered to the pulverizer via a conveyor or feeder system, and then subjected to high-impact forces such as rotation, pressure, friction, or collision, depending on the pulverizer’s design. As materials are processed, additional steps like cooling, heating, or aerating may be integrated to alter or preserve desired properties.

A key advantage of industrial pulverizer machines is their adjustable settings. Operators can tailor the fineness of the output by modifying variables such as grinding speed, pressure, or screen size. This flexibility enables precise control over particle size distribution, which is critical for applications ranging from pharmaceutical ingredient milling to mineral ore refinement, food ingredient homogenization, and powder coating production.

Looking to understand which pulverizer is right for your application? Consider your required output particle size, material hardness, desired throughput, and contamination sensitivity. For more information, explore our pulverizer manufacturer listings or contact leading suppliers for application-specific recommendations.

Types of Pulverizers

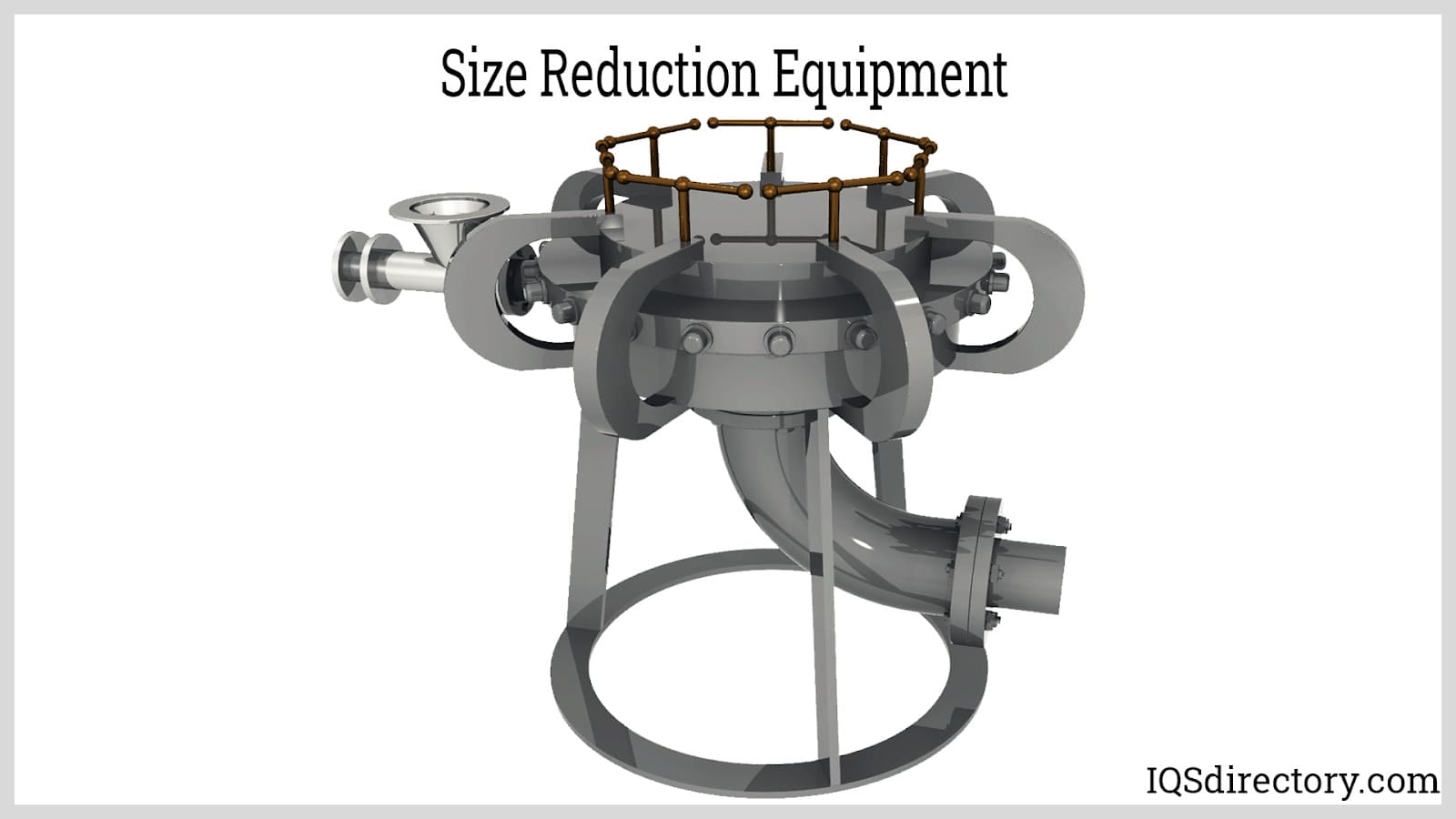

Industrial pulverizers are generally categorized into three main types: crushers, impactors, and grinding mills. Each type is tailored to specific material characteristics, reduction requirements, and end-use applications. Understanding these categories is fundamental for those specifying size reduction solutions.

- Crushers: Designed to reduce large, dense materials such as rock, stone, metal, or concrete into smaller gravel, chips, or dust. Crushers are essential in primary size reduction, recycling, mineral extraction, and demolition waste management.

- Impactors (Impact Crushers): Utilize high-energy collisions to shatter and reduce material size. Impact crushers are well-suited for brittle materials or those requiring a cubical product. They are commonly employed in recycling, mining, and aggregate production.

- Grinding Mills: Employ friction and grinding media (such as balls, rods, or hammers) to progressively refine materials into fine powders or slurries. Grinding mills are central to industries like pharmaceuticals, chemicals, food processing, mineral beneficiation, and pigment manufacturing.

Grinding Mills

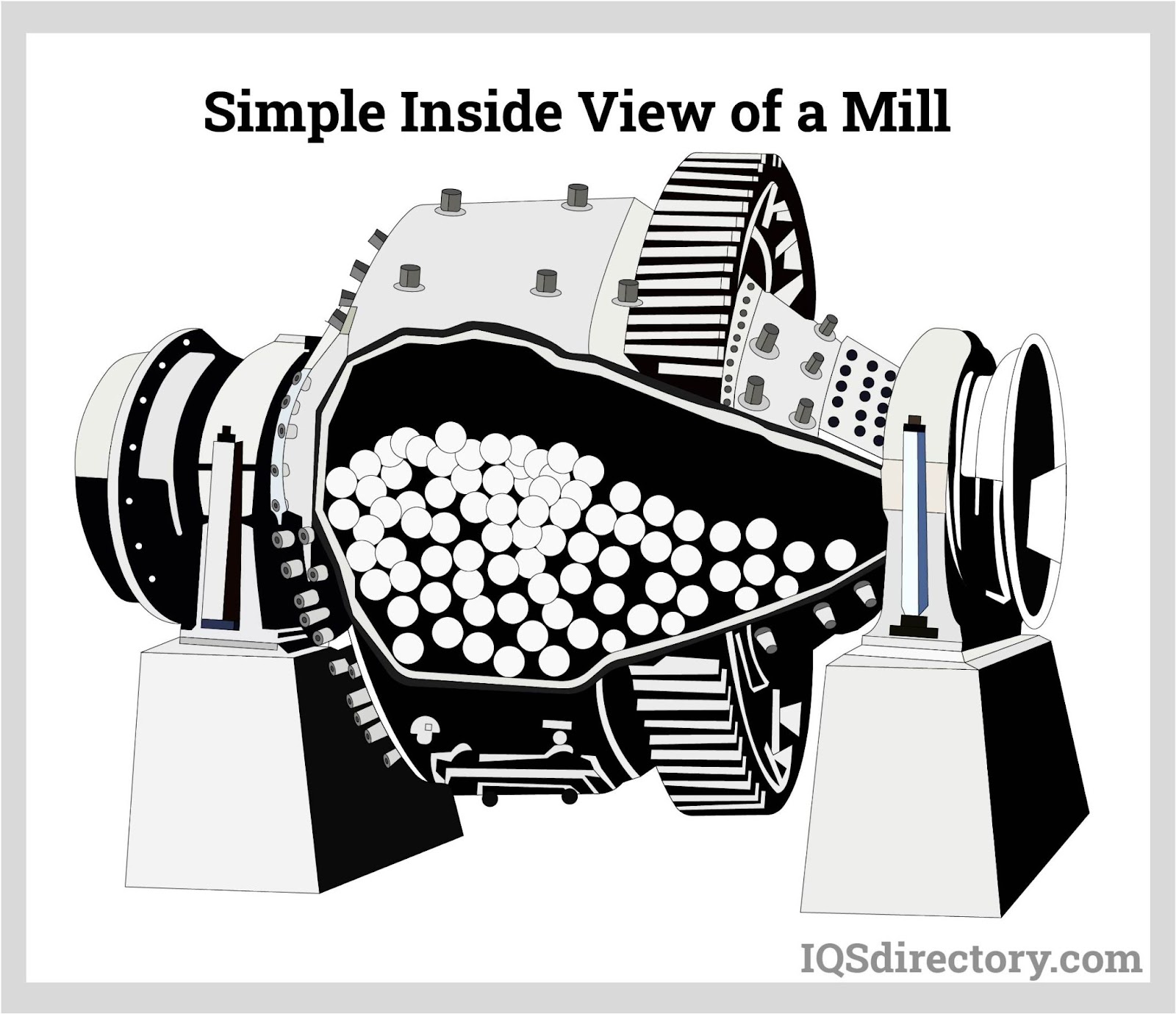

Grinding mills are the workhorses of many industrial material processing lines, enabling the breakdown of bulk solids into fine powders for downstream use. These mills utilize grinding media—such as steel balls, rods, ceramics, brass, bronze, or flint—to apply consistent force and abrasion.

Among the most prevalent designs are ball mills and hammer mills:

- Ball Mills: Featuring a horizontally mounted, rotating cylinder lined with wear-resistant material, ball mills contain steel balls or rods as the grinding media. As the cylinder rotates, the media tumble and crush the material through impact and attrition. Ball mills are ideal for achieving ultra-fine powders and are used in mineral processing, cement manufacturing, and powder metallurgy. For detailed specifications and supplier options, see our Ball Mill directory.

- Hammer Mills: These mills employ rapidly rotating hammers mounted in a vertical or horizontal plane to shatter materials. Primarily used in agriculture for grinding chaff, grains, and feedstock, hammer mills are also employed in wood processing, biomass pelletizing, and recycling operations. Their robust design and efficient throughput make them suitable for both fine and coarse grinding tasks.

- Tube Mills: Similar in operation to ball mills, tube mills are larger and often used in cement and mineral processing plants. They process material by introducing a slurry of ground solids and water at one end, which is subsequently pulverized and discharged as a fine slurry at the opposite end. Tube mills’ design ensures thorough mixing and fine grinding, particularly for large-scale production.

Did you know? Choosing the right grinding media is crucial for product quality and contamination control. For sensitive or hazardous materials, non-sparking media like ceramics or flint are preferred.

Crushers

Crushers are indispensable in mining, construction, and recycling sectors for reducing raw material size, simplifying separation, and facilitating handling or further processing. The most widely used variety is the jaw crusher, but other options such as gyratory and cone crushers are also common.

- Jaw Crushers: Operate with two jaws—one stationary and one movable (the swing jaw). Material is crushed as the swing jaw moves toward the fixed jaw. Jaw crushers are subdivided into:

- Blake Crushers: Swing jaw fixed at the upper position, suitable for heavy-duty crushing and coarse feed.

- Dodge Crushers: Swing jaw fixed at the lower position, suitable for finer crushing applications.

- Universal Crushers: Swing jaw fixed at an intermediate position, offering versatility for medium to coarse reduction.

- Gyratory Crushers: Used for primary or secondary reduction in mining and ore processing. These feature a conical head and concave surface, with crushing action generated by eccentric motion—ideal for high-capacity, continuous operations.

- Cone Crushers: Similar to gyratory crushers but with a less steep crushing chamber and secondary/tertiary crushing capability. Cone crushers are best for reducing mid-hard to hard ores and rocks. Subtypes include:

- Compound (VSC series) cone crushers

- Symons (spring) cone crushers

- Single cylinder hydraulic cone crushers

- Multi-cylinder hydraulic cone crushers

Which crusher is best for your operation? Consider material hardness, desired product size, throughput requirements, and space constraints. For guidance, check out our Jaw Crusher Manufacturers page.

Impactors

Impactors (or impact crushers) use high-velocity impacts rather than compressive force to break materials. Material is fed into a chamber where it is struck by rapidly moving blow bars or plates, causing fragmentation. The resulting fragments exit through strategically placed openings.

- Applications: Ideal for recycling concrete and asphalt, crushing brittle or friable materials, aggregate production, and reducing construction waste.

- Designs: Available as horizontal shaft impactors (HSI) and vertical shaft impactors (VSI), each optimized for specific feed characteristics and output shapes.

- Specialized Pulverizer Types:

- MPS Mills: Also called vertical spindle roller mills, these use tire-like rollers to grind coal for power generation. Coal is fed centrally and ground by rolling action over a grinding table.

- Bowl Mills: Employ tires to pulverize coal, available as shallow or deep bowl configurations for different grind fineness and throughput.

Pulverizers are further classified by operational speed:

- Low-speed machines (e.g., ball mills, tube mills): Robust, high-capacity, suited for coarse grinding.

- Medium-speed machines (e.g., ring and ball mills, MPS mills, bowl mills): Offer balanced throughput and fineness for industrial processes.

- High-speed machines (e.g., attrition mills, jet pulverizers): Deliver exceptional efficiency and fine particle control, ideal for advanced manufacturing and specialty chemicals.

Pulverizer Equipment Components

While each pulverizer type has unique features, most share common core components:

- Entry Feed System: Controls the rate and consistency of material input, often via hoppers, screw feeders, or conveyor belts.

- Rotating Mechanism: Such as drums, rotors, or discs, responsible for imparting energy to the material.

- Grinding Elements: Balls, rods, hammers, or rollers interact with the material, breaking it down through force and abrasion.

- Exit Feed System: Channels the finished product out of the machine; may include screens or classifiers for grading.

- Auxiliary Systems: Airflow, temperature regulation, and dust collection systems may be included for process control, product quality, and environmental compliance.

- Safety Features: Automatic shut-off, interlocks, guards, sensors, and barrier systems ensure operator safety and regulatory compliance.

Looking for specific replacement parts or upgrades? Many manufacturers offer customized retrofits, advanced control panels, and aftermarket support to enhance machine longevity and performance.

Designing Pulverizer Equipment

Designing or specifying a pulverizer system requires careful consideration of operational goals and material properties. Key design criteria include:

- Feed Quantity & Consistency: Determines required machine capacity and throughput.

- Material Breaking Behavior: Some materials fracture easily, while others are ductile or elastic, affecting the type of pulverizer best suited.

- Initial Texture & Hardness: Coarse, abrasive, or sticky materials may necessitate specialized liners or wear-resistant components.

- Cleanliness & Contaminant Sensitivity: For pharmaceutical and food processing, stainless steel construction and easy-clean features are essential.

- Required Finished Texture: Defines the necessary fineness, particle size distribution, and homogeneity.

Manufacturers use these criteria to optimize machine selection—choosing between batch or continuous operation, integrating airflow or temperature control for heat-sensitive materials, and determining the most efficient grinding mechanisms for the application.

Not sure what configuration you need? Request a material analysis or pilot-scale trial from leading pulverizer suppliers to validate your process requirements before purchase.

Pulverizer Safety and Standards

Industrial pulverizers can pose significant hazards if improperly designed, installed, or operated. Regulatory compliance is paramount for both operator safety and process reliability. In the United States, the Occupational Safety and Health Administration (OSHA) sets forth requirements for safe workplace practices, lockout/tagout procedures, guarding, and dust mitigation.

Additional standards are provided by organizations such as the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME). Some industries, including pharmaceuticals and food, may also require conformity with FDA and cGMP (current Good Manufacturing Practices) standards.

- Common Pulverizer Safety Features:

- Emergency stop and automatic shutdown controls

- Protective barriers, interlocks, and guardrails

- Explosion venting and dust collection systems

- Operator training and maintenance protocols

Are you compliant with industry safety standards? Consult with experienced manufacturers and review OSHA, ANSI, and ASME guidelines regularly to ensure safe and legal operation.

Purchasing Pulverizers

Selecting the ideal pulverizer system is a critical step in optimizing your production workflow and achieving target product specifications. The buying process is best approached as a partnership between your in-house team and a reputable manufacturer with proven expertise in your industry.

Key factors to consider when evaluating pulverizer manufacturers and suppliers:

- Application Expertise: Does the manufacturer demonstrate experience with your material type and industry-specific requirements?

- Machine Quality & Customization: Are systems engineered for durability, efficiency, and easy maintenance? Is customization available for unique processing needs?

- Project Scope & Budget: Consider initial investment, operational costs, energy efficiency, and return on investment.

- Lead Times & Delivery Preferences: Ensure that production schedules align with your project deadlines.

- Aftermarket Support: Evaluate the availability of installation services, technical support, spare parts, and preventive maintenance programs.

We recommend starting your search with the trusted manufacturers listed on this page, each offering unique advantages in technology, service, and support. Review company profiles and product literature, and shortlist three or four suppliers for initial discussions. Ask for references, case studies, and, where possible, schedule plant tours or demonstrations. Compare offerings, ask probing questions about machine performance, scalability, and maintenance, and select the partner that best aligns with your goals.

Ready to take the next step? Contact top pulverizer manufacturers today to request a quote, schedule a consultation, or arrange for sample testing.

Pulverizer Applications, Benefits, and Use Cases

Pulverizers are integral to modern material processing, providing solutions for:

- Pharmaceutical Manufacturing: Achieve consistent particle size for tablet production, APIs, and excipients.

- Food Processing: Grind grains, spices, flour, sugar, and additives for uniform blending and improved shelf stability.

- Recycling & Waste Management: Shred and reduce plastics, rubber, metals, and electronic waste for easier sorting, melting, or reuse.

- Construction & Demolition: Pulverize concrete, brick, and asphalt for road base, fill material, or reprocessing.

- Mining & Aggregate: Crush ore, minerals, and rock for downstream beneficiation and value-added processing.

- Power Generation: Pulverize coal, biomass, or alternative fuels for efficient combustion in boilers and kilns.

- Chemical and Pigment Production: Ensure optimal surface area and reactivity for paints, coatings, and specialty chemicals.

- Soil and Agricultural Processing: Prepare soil for planting, mix fertilizers, or produce animal feed with precise particle size control.

- Laboratory and Analytical Testing: Prepare small samples with consistent particle size for accurate analysis and research.

Benefits of Using Pulverizers:

- Increase process efficiency and throughput

- Enhance material homogeneity and product quality

- Reduce waste and disposal costs

- Enable recycling and circular economy initiatives

- Improve downstream processing and equipment compatibility

- Support compliance with safety and hygiene standards

Decision Factors for Choosing a Pulverizer

Choosing the right pulverizer involves balancing technical and operational priorities:

- Material Characteristics: Hardness, abrasiveness, moisture content, and chemical reactivity.

- Desired Particle Size: Range of fineness, uniformity, and requirements for downstream use.

- Capacity & Throughput: Volume of material processed per hour or shift.

- Energy Consumption: Power requirements, energy efficiency, and environmental impact.

- Maintenance & Downtime: Ease of cleaning, accessibility of wear parts, and service intervals.

- Automation & Integration: Compatibility with other plant systems, process controls, and digital monitoring.

- Regulatory Compliance: Industry-specific standards for safety, hygiene, and emissions.

Still have questions? Try searching for “how to select a pulverizer for coal grinding,” “best pulverizer for recycling applications,” or “pulverizer maintenance tips” to explore detailed guides and expert advice tailored to your needs.

Frequently Asked Questions (FAQ) About Pulverizers

- What is the difference between a pulverizer and a grinder?

While both pulverizers and grinders reduce material size, pulverizers generally refer to heavy-duty machines for industrial-scale reduction, whereas grinders often describe smaller or lighter-duty equipment for finer grinding and finishing. - How do I determine the right pulverizer size for my facility?

Consider your daily throughput, material feed size, and desired output particle size. Consult with manufacturers for a material analysis and machine sizing recommendations. - What maintenance is required for industrial pulverizers?

Routine inspection, lubrication, wear part replacement, and periodic calibration are necessary to ensure safe, consistent operation. Automated monitoring systems can further reduce downtime and optimize maintenance schedules. - Can a pulverizer process multiple material types?

Some machines are designed for multi-material use, while others are optimized for a single material or class. Always verify with the manufacturer regarding compatibility and cleaning procedures to prevent cross-contamination. - What industries benefit most from pulverizer equipment?

Key industries include mining, agriculture, construction, food and beverage, pharmaceuticals, chemicals, power generation, and recycling.

For more in-depth answers and troubleshooting, visit our pulverizer manufacturer listings or consult with industry experts.

Start Your Pulverizer Selection Journey

Ready to invest in a new pulverizer or upgrade your existing system? Take the next step by exploring the latest models, comparing features, and requesting quotes from trusted manufacturers. Whether you need a high-capacity coal pulverizer for power generation, a precision grinder for pharmaceuticals, or a versatile recycling shredder, our directory connects you with the industry’s best.

Explore, compare, and choose with confidence:

- Visit our comprehensive manufacturer directory

- Request application-specific advice and sample testing

- Compare maintenance plans, warranties, and support services

- Ask for references and real-world case studies

- Stay up-to-date with emerging pulverizer technologies and trends

Enhance your process, reduce costs, and achieve superior material quality with the right pulverizer solution—engineered for your industry and your success.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services