Size reduction is an important part of many industrial processes, making ball mills and other pulverizing mechanisms vital to these industries and in high demand. Particularly in processes that involve the mixing of materials, the smaller the particulate size of the materials to be mixed, the easier and more complete the mixing will be. Ball mills are useful tools for metal alloying processes for this reason; they can crush and grind the constituent materials into very small particles, which makes them easier to combine. Read More…

Here at Granutech-Saturn Systems we manufacture high performance equipment which can handle the toughest projects. Our Saturn Hammermills are engineered to meet the specific requirements of a variety of applications.

At Williams Patent Crusher & Pulverizer Co., we are industry leaders in the design and manufacture of high-performance pulverizers that set the standard for reliability, efficiency, and innovation. Since our establishment, we have remained committed to creating cutting-edge solutions that meet the diverse and demanding needs of industries such as mining, power generation, recycling, and more.

We are a trusted partner in delivering innovative size reduction solutions, and at DP Pulverizers Americas Inc., we have built our reputation on precision engineering, consistent quality, and a commitment to advancing material processing technology. Our expertise lies in designing and manufacturing size reduction equipment that meets the demanding needs of industries requiring efficient and...

More Ball Mill Manufacturers

What Is a Ball Mill? Principles, Design, and Industrial Applications

Ball mills are highly versatile industrial grinding machines, widely used for particle size reduction across a diverse array of materials. Common applications include the processing of black powder, cement, fertilizers, silicates, and both ferrous and non-ferrous metals. Ball mills are also essential equipment in the mining, chemical, pharmaceutical, ceramics, and food processing industries, serving as a cornerstone in material preparation and mixing operations.

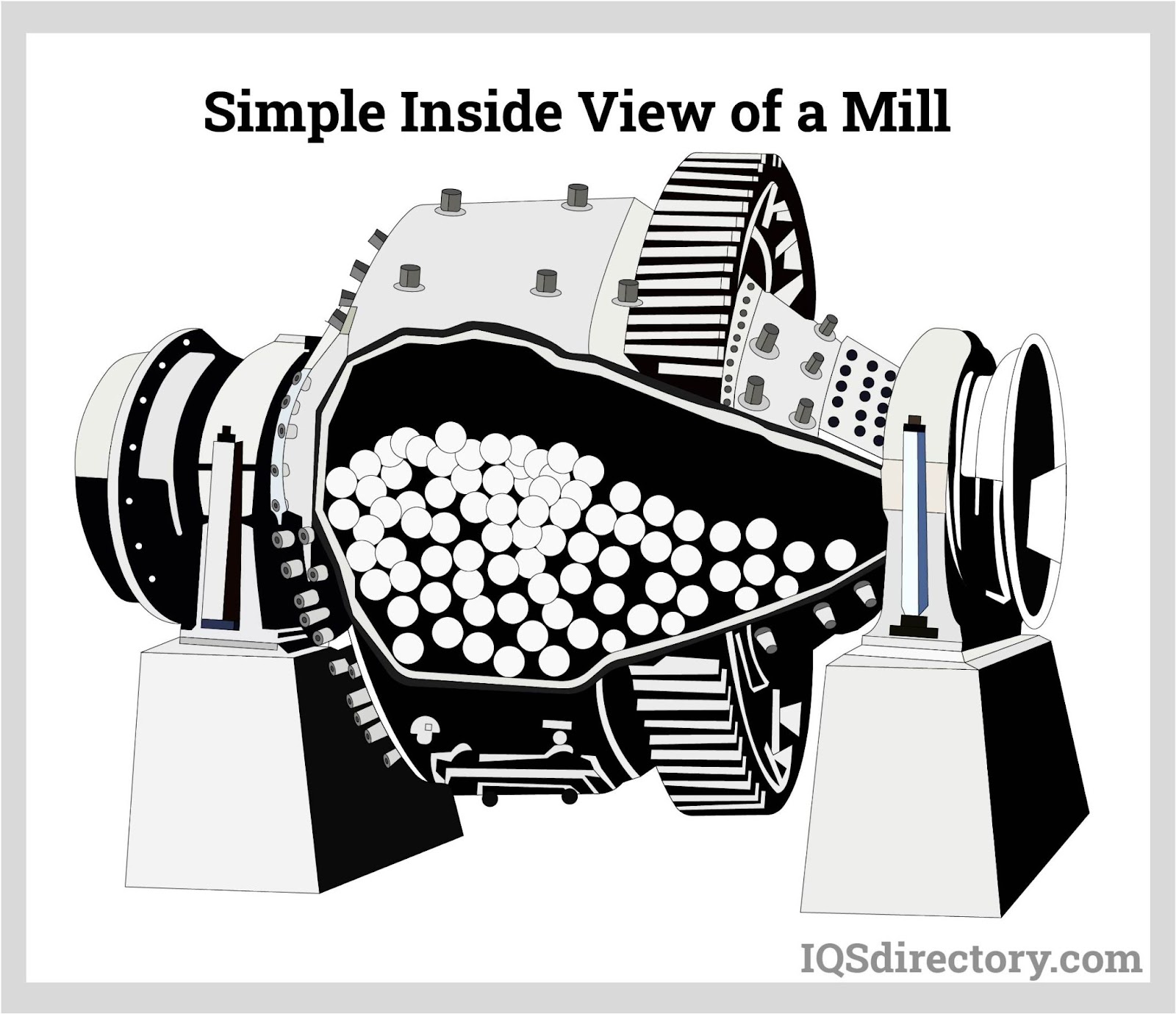

The basic design and operation of a ball mill closely resemble that of a rock tumbler—both employ a rotating cylinder, filled with milling media, to grind, blend, or polish materials. However, industrial ball mills are engineered for high-capacity, precision-controlled grinding and are available in a range of configurations to suit specific production requirements—from lab-scale batch operations to large-scale, continuous processing.

Ball Mill Construction: Key Components and Material Considerations

A typical ball mill machine consists of several critical components:

- Cylinder: The core grinding chamber, usually fabricated from steel, stainless steel, or ceramic, which houses both the material to be milled and the grinding media.

- Motor and Drive System: Powers the rotation of the cylinder at controlled speeds to achieve optimal grinding efficiency.

- Grinding Media: The balls or other shapes that perform the actual grinding. Materials for grinding media include hardened steel, stainless steel, ceramic, flint, and composite materials. Choice of media impacts grinding efficiency, contamination risk, and final particle size distribution.

- Feed and Discharge Mechanisms: Allow loading of raw materials and removal of processed product. Ball mills may feature batch or continuous feed/discharge systems, depending on the production process.

How Ball Mills Work: The Grinding Process Explained

During operation, the mill cylinder is loaded with grinding media and the material to be processed. As the powerful motor rotates the cylinder, the grinding media tumble and cascade, generating impact and attrition forces that break down the material into fine powders or specific particle sizes. The efficiency of the milling process is influenced by factors such as:

- Rotational speed

- Type and size of grinding media

- Material hardness and abrasiveness

- Mill load and filling ratio

- Duration of milling

For users seeking advice on optimizing ball mill performance: What factors most affect particle size distribution and throughput in industrial ball milling operations?

Batch vs. Continuous Ball Milling

Ball milling can be performed as a batch process—where a set quantity of material is milled for a predetermined time—or as a continuous process, where materials are automatically loaded and discharged. Continuous ball mills are favored in high-volume industrial applications, such as mineral processing, cement production, and large-scale chemical manufacturing.

Common Uses and Industry-Specific Applications of Ball Mills

The adaptability of ball mills makes them an indispensable tool across multiple industries. Here are some of the most common use cases:

- Mining and Mineral Processing: Ball mills are critical in ore dressing operations, used for grinding and blending ores prior to extraction processes. This includes gold, copper, iron, and other precious and base metals.

- Cement Manufacturing: Ball mills crush clinker and other raw materials into fine powder, forming the basis of cement production. Their robust construction is ideal for handling abrasive materials and high throughput demands.

- Powdered Chemicals and Pharmaceuticals: In chemical and pharmaceutical industries, ball mills enable precise control over particle size, crucial for product consistency and bioavailability.

- Ceramics and Glass: Ball mills are used to grind and blend materials for the production of ceramics, glazes, and glass, ensuring homogeneous mixtures and optimal firing characteristics.

- Food Processing: Certain food ingredients require fine grinding or mixing, and ball mills offer a hygienic, contamination-resistant solution for spice, nut, or grain processing.

- Battery and Advanced Materials: Ball mills are increasingly used for manufacturing battery electrode materials, nanomaterials, and specialty powders requiring ultra-fine grinding and strict quality control.

Are you searching for a ball mill for a specific industry or process? Explore our Industries Served page for tailored solutions and expert guidance.

Key Benefits and Advantages of Ball Milling Technology

When evaluating ball milling systems for your application, consider the following advantages:

- Versatility: Suitable for both wet and dry grinding; capable of handling a wide range of materials, including hard, brittle, fibrous, or abrasive substances.

- Precise Particle Size Control: Adjustable operational parameters allow for fine-tuning of final product size and distribution.

- Uniform Mixing and Blending: Effective for homogenizing multi-component mixtures and facilitating chemical reactions in solid-state synthesis.

- Scalability: Available in laboratory, pilot, and full-scale production models—ideal for R&D up to mass manufacturing.

- Cost-Effectiveness: Lower capital and operational expenses compared to other milling and grinding technologies, especially for medium to coarse products.

- Durability and Low Maintenance: Robust design and high-quality materials ensure long service life and minimal downtime.

Types of Ball Mills: Choosing the Right Model for Your Application

The ball mill market includes a variety of machine types, each designed for specific processing goals and industry needs. Common types include:

- Horizontal Ball Mills: The most prevalent design; suitable for general-purpose grinding in mining, cement, and chemical industries.

- Vertical Ball Mills: Offer a smaller footprint and are used for fine grinding and dispersion in specialty chemical and pharmaceutical applications.

- Planetary Ball Mills: Feature multiple grinding stations for high-energy milling and ultra-fine particle creation—ideal for research labs and advanced material development.

- Attritor Ball Mills: Also known as stirred ball mills, these use an agitator to accelerate media motion, delivering rapid, efficient milling for fine particle production.

- Vibratory Ball Mills: Employ vibration to facilitate grinding, often used for rapid pulverization of small sample volumes.

Key Factors to Consider When Selecting a Ball Mill

When investing in a new ball mill, it’s crucial to evaluate several factors to ensure optimal performance and return on investment:

- Material Characteristics: Hardness, abrasiveness, moisture content, and chemical properties can influence grinding efficiency and media selection.

- Target Particle Size: Desired final particle size distribution determines milling duration, media type, and operational parameters.

- Capacity Requirements: Throughput needs, batch versus continuous operation, and scalability to future production volumes.

- Contamination Sensitivity: For applications requiring ultra-pure products (e.g., pharmaceuticals, advanced materials), select appropriate media and lining materials.

- Maintenance and Ease of Cleaning: Design features that facilitate routine maintenance, cleaning, and media replacement can reduce operational downtime.

- Energy Efficiency: Newer ball mill models offer enhanced energy-saving designs, reducing operational costs and environmental impact.

- Integration with Downstream Processes: Consider how the ball mill will interface with feeders, classifiers, dryers, or packaging systems.

Comparing Ball Milling with Alternative Grinding Technologies

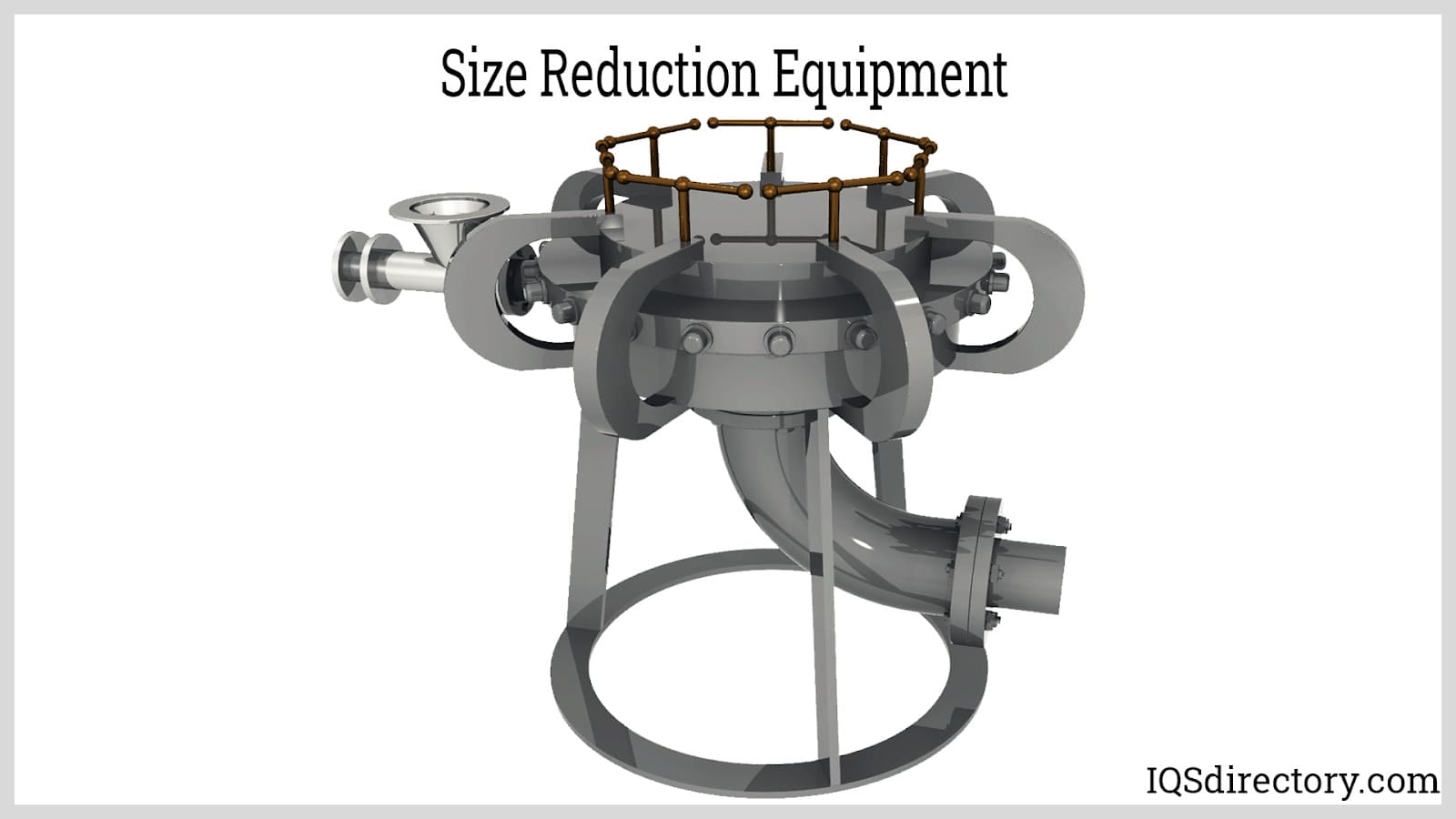

While ball mills are a popular solution for many grinding and pulverizing tasks, alternative technologies may be better suited for specific applications. Common alternatives include:

- Jet Mills: Use high-velocity air streams to grind materials, ideal for ultra-fine powders and heat-sensitive substances.

- Hammer Mills: Employ hammers or blades to pulverize materials, suited for coarse grinding of brittle or fibrous materials.

- Roller Mills: Crush materials between rotating cylinders, used extensively in food processing and cement industries.

- Attrition Mills: Grind materials by friction and shear, effective for producing uniform particle sizes in chemical and food processing.

Curious about which grinding solution fits your material or process? Request a consultation or explore our comprehensive range of industrial pulverizers and mills to compare capabilities.

Frequently Asked Questions About Ball Mills

- What maintenance is required for a ball mill?

Routine checks include inspecting linings, lubricating bearings, monitoring drive system performance, and periodic replacement of worn grinding media. Preventive maintenance helps maximize uptime and extend equipment lifespan. - How do I optimize energy consumption in ball milling?

Choose the correct media size, optimize rotational speed, maintain optimal loading, and consider modern energy-efficient mill designs. Automation and real-time monitoring can further reduce power usage. - Can ball mills be customized for specific processes?

Yes, reputable manufacturers offer custom engineering, including tailored drum sizes, lining materials, discharge mechanisms, and integrated process controls for unique requirements. - What safety considerations are important in ball milling?

Ensure the system is equipped with emergency stops, appropriate guards, dust collection, and explosion mitigation features, especially when grinding combustible or hazardous materials.

Ready to Take the Next Step?

If you’re looking to purchase a ball mill, upgrade existing milling equipment, or simply gather more technical information, our team of process engineers and product specialists is here to help. We provide comprehensive support from project scoping and equipment selection to installation, commissioning, and after-sales service.

Start your search for the ideal ball mill:

Still have questions? Contact us today to discuss your application, request a quote, or schedule a process evaluation with our experts.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services