There are many different types of crushers, and some of the most widely used types are jaw crushers, gyratory crushers and cone crushers. Jaw crushers and gyratory crushers work well on both soft and hard materials and are often utilized in industries such as mining, for reduction of large quarried materials such as ore; construction, to reduce large building materials such as stone and concrete; and industrial manufacturing, for the processing of large, dense materials. Read More…

Here at Granutech-Saturn Systems we manufacture high performance equipment which can handle the toughest projects. Our Saturn Hammermills are engineered to meet the specific requirements of a variety of applications.

At Williams Patent Crusher & Pulverizer Co., we are industry leaders in the design and manufacture of high-performance pulverizers that set the standard for reliability, efficiency, and innovation. Since our establishment, we have remained committed to creating cutting-edge solutions that meet the diverse and demanding needs of industries such as mining, power generation, recycling, and more.

We are a trusted partner in delivering innovative size reduction solutions, and at DP Pulverizers Americas Inc., we have built our reputation on precision engineering, consistent quality, and a commitment to advancing material processing technology. Our expertise lies in designing and manufacturing size reduction equipment that meets the demanding needs of industries requiring efficient and...

More Crusher Manufacturers

Industrial Crushers: Essential Equipment for Material Size Reduction

Industrial crushers—including cone crushers, jaw crushers, gyratory crushers, and specialized machines such as auto flatteners—play a vital role across a wide array of industries that require efficient material processing and size reduction. These robust machines are engineered to handle the toughest materials, providing solutions for mining, construction, recycling, metallurgy, and chemical processing sectors. Choosing the right type of crusher is crucial for optimizing operational efficiency, ensuring product consistency, and minimizing operational costs.

What Are Cone Crushers and What Are Their Primary Applications?

Cone crushers are renowned for their effectiveness in secondary, tertiary, and even quaternary crushing stages. Best-suited for medium to very hard materials, these machines are indispensable in industries such as:

- Metallurgical Processing: Crushing large aggregates supplied by metal mining operations, including iron ore, copper ore, and other hard rock minerals.

- Road Construction: Reducing building materials such as asphalt, concrete, and recycled aggregates for use in infrastructure projects.

- Chemical Manufacturing: Processing minerals like phosphate and silicic acid for use in chemical synthesis and production lines.

- Aggregate Production: Creating uniform particle sizes for use in ready-mix concrete, road base, and landscape materials.

- Mining Operations: Initial and secondary crushing of mined materials before further processing or shipping.

How Do Crushers Work? Understanding the Crushing Mechanism

Crushers function by breaking apart or compressing materials using a force supplied by mechanical means. This process involves transferring force through a material that is molecularly stronger than the substrate being processed. Crushers typically hold materials between two robust, parallel surfaces and then apply enough pressure to fracture or deform the materials, reducing them to the desired size.

- Compression Crushing: This method relies on squeezing materials between rigid surfaces, making it highly effective for hard, brittle materials.

- Impact Crushing: Some crushers, such as impact crushers, use high-speed force to shatter materials, ideal for softer or more friable substances.

- Shear and Attrition: Certain designs employ shearing and grinding actions to reduce particle size, which is useful in recycling or waste processing applications.

Types of Industrial Crushers: Jaw, Gyratory, and Cone Crushers Compared

Understanding the differences between crusher types is fundamental for selecting the right equipment for your application. Each type offers unique advantages depending on material characteristics, throughput requirements, and operational environment:

- Jaw Crushers: Characterized by a set of large, vertical "jaws"—one stationary and one mobile—jaw crushers are highly effective for primary crushing. The movement of the mobile jaw generates the necessary compression force to break down large, coarse materials. Jaw crushers are prevalent in mining, demolition, and recycling operations thanks to their robust design and versatility in handling various feed sizes.

- Gyratory Crushers: Similar in principle to jaw crushers but with a conical design, gyratory crushers feature a concave surface and a conical head. The crushing action is generated by an eccentric arrangement, providing continuous, high-capacity crushing for large-scale mining and heavy-duty aggregate plants. They are ideal for processing tough, abrasive materials and are often used as primary crushers in mining operations.

- Cone Crushers: Cone crushers, while related to gyratory crushers, have an even more pronounced conical profile. They feature a large top opening for feeding bulky materials and a smaller bottom outlet for discharging the finely crushed product. The core crushing action occurs between an eccentrically gyrating spindle and a concave hopper lined with wear-resistant materials. Cone crushers are optimized for secondary and tertiary size reduction and excel at producing uniform, cubically shaped aggregates.

Need help deciding between jaw, gyratory, or cone crushers for your facility? Contact our crusher experts for personalized recommendations based on your specific material and throughput needs.

Expanding Your Crushing Operation: Specialized Crushers and Applications

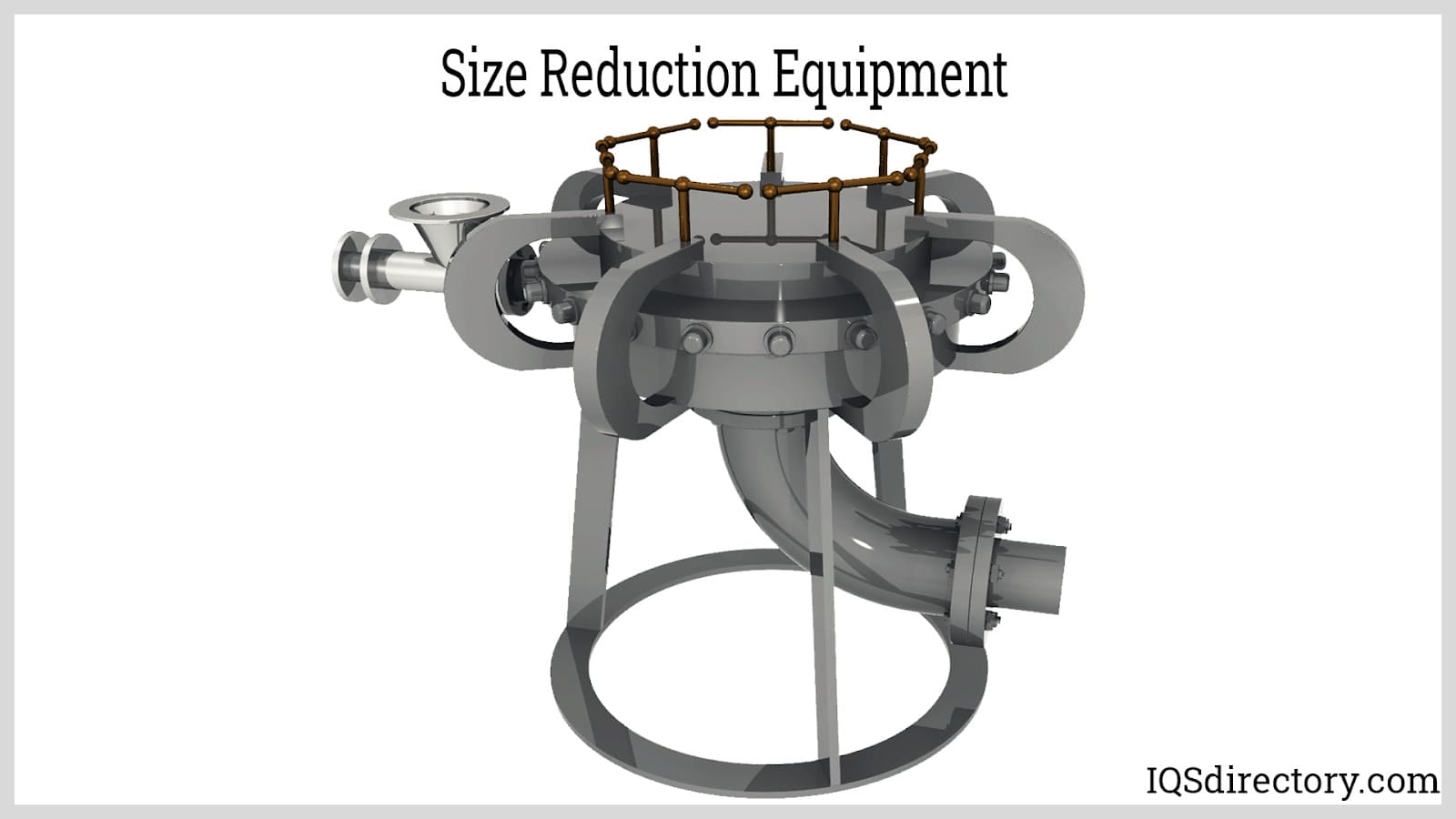

In addition to standard jaw, gyratory, and cone crushers, several specialized machines are available to address unique industrial requirements:

- Auto Flatteners and Car Crushers: Machines like the Granutech-Saturn Big Mac Auto Flattener are engineered for automotive recycling, efficiently compressing vehicles and scrap metal for transport and further processing. These crushers streamline operations in scrap yards and metal recycling facilities, reducing the volume of waste and maximizing material recovery.

- Impact Crushers: Ideal for applications requiring high reduction ratios and superior particle shape, impact crushers are extensively used in the production of recycled concrete aggregate, asphalt recycling, and construction demolition waste processing.

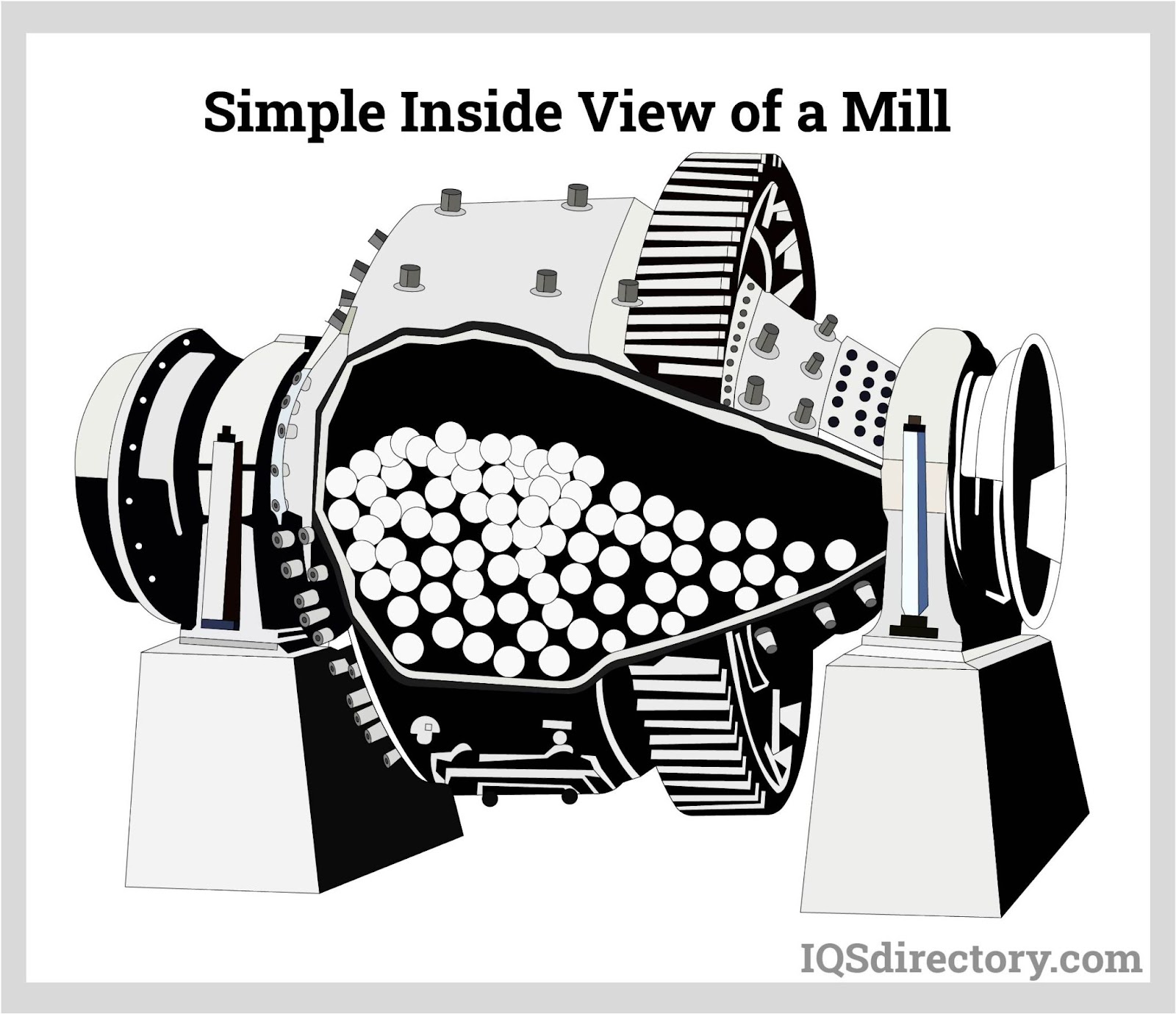

- Hammer Mills & Pulverizers: For materials that require fine grinding or ultra-fine material reduction, hammer mills and industrial pulverizers provide a reliable solution, particularly in pharmaceutical manufacturing, food processing, and chemical engineering.

Key Benefits of Using Industrial Crushers

Implementing the right industrial crusher in your operation brings a host of tangible benefits, including:

- Increased Efficiency: Automated crushing processes reduce manual labor, speed up throughput, and lower operating costs.

- Consistent Particle Size: Achieve uniform material size, vital for downstream processing, product quality, and meeting industry specifications.

- Enhanced Material Recovery: Improve yield from mining, demolition, and recycling processes by efficiently breaking down tough materials.

- Reduced Environmental Impact: Minimize waste volume and facilitate the recycling of valuable materials, supporting sustainability initiatives.

- Scalability: Modern crushers offer modular designs and flexible configurations to grow with your operational needs.

How to Select the Right Crusher for Your Application

Choosing the proper crusher involves evaluating several critical factors to ensure optimal performance and return on investment. Consider the following decision points:

- Material Characteristics: Assess hardness, abrasiveness, moisture content, and particle size distribution.

- Desired Output Size: Depending on downstream processes, select a crusher that produces the required product gradation.

- Capacity Requirements: Estimate the necessary throughput to meet production goals and avoid bottlenecks.

- Operating Environment: Evaluate space constraints, energy consumption, and potential integration with existing systems.

- Maintenance and Wear Parts: Factor in ease of maintenance, availability of replacement parts, and total cost of ownership.

- Safety and Compliance: Ensure the crusher meets industry standards and workplace safety regulations.

Industrial Crusher Use Cases and Applications

Industrial crushers are engineered to serve a variety of use cases, including:

- Mining: Primary and secondary crushing of mined ore to facilitate further processing or direct sale.

- Construction & Demolition: Crushing concrete, asphalt, brick, and other construction materials for recycling or disposal.

- Metals Recycling: Processing scrap metal, old vehicles, and industrial waste for re-melting or resale.

- Aggregate Production: Manufacturing sand, gravel, and crushed stone for commercial construction and infrastructure projects.

- Chemical Processing: Reducing minerals and industrial byproducts for use in chemical synthesis or as feedstock for manufacturing.

- Waste Management: Compacting bulky waste to reduce landfill volume and facilitate efficient disposal or recycling.

Frequently Asked Questions About Industrial Crushers

- What size and type of crusher do I need for my material?

Material hardness, particle size, and required throughput all influence the optimal choice. Our >crusher selection guide can help you identify the best fit. - Can crushers process mixed or contaminated materials?

Many modern industrial crushers are designed to handle mixed feedstocks, including contaminated or variable materials. Consult our technical experts for tailored recommendations. - What safety features are available on contemporary crushers?

Features such as automatic overload protection, dust suppression systems, and emergency stop controls enhance operator safety. Explore crusher safety solutions now. - How can I improve energy efficiency in my crushing operation?

Upgrading to energy-efficient motors, optimizing feed rates, and selecting the right crusher type can all improve energy usage. Find out more in our energy efficiency guide.

Why Choose Granutech-Saturn Crushers? Industry-Leading Solutions and Support

Granutech-Saturn Systems is a recognized leader in the design and manufacturing of industrial crushers and material reduction equipment. With decades of engineering expertise, we deliver robust, reliable, and innovative solutions tailored to your operational demands. Our crushers are built to maximize uptime, minimize maintenance, and deliver consistent output, whether you operate in mining, recycling, construction, or chemical processing sectors.

- Proven Performance: Trusted by industry leaders worldwide, Granutech-Saturn crushers deliver superior results across countless installations.

- Comprehensive Product Line: From jaw and cone crushers to auto flatteners and specialized systems, we offer solutions for every material processing challenge.

- Expert Engineering Support: Our team provides application engineering, commissioning, and ongoing technical support to ensure your long-term success.

- Turnkey Solutions: We offer complete systems integration, from initial concept to installation and operator training.

Ready to upgrade your material processing capabilities? Request a custom crusher quote and speak with our experts about your requirements today.

Start Your Crusher Research: Next Steps for Buyers and Specifiers

- How do I compare crusher models and find the best value for my operation?

- What are the latest advancements in crusher design and automation?

- How can I optimize my entire material processing line for throughput and efficiency?

- Where can I find detailed technical specifications and case studies?

- Who offers field service, maintenance, and operator training for industrial crushers?

For further information on crushers, material processing equipment, and turnkey solutions, contact the Granutech-Saturn team—your trusted partner for advanced crushing technology and support.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services