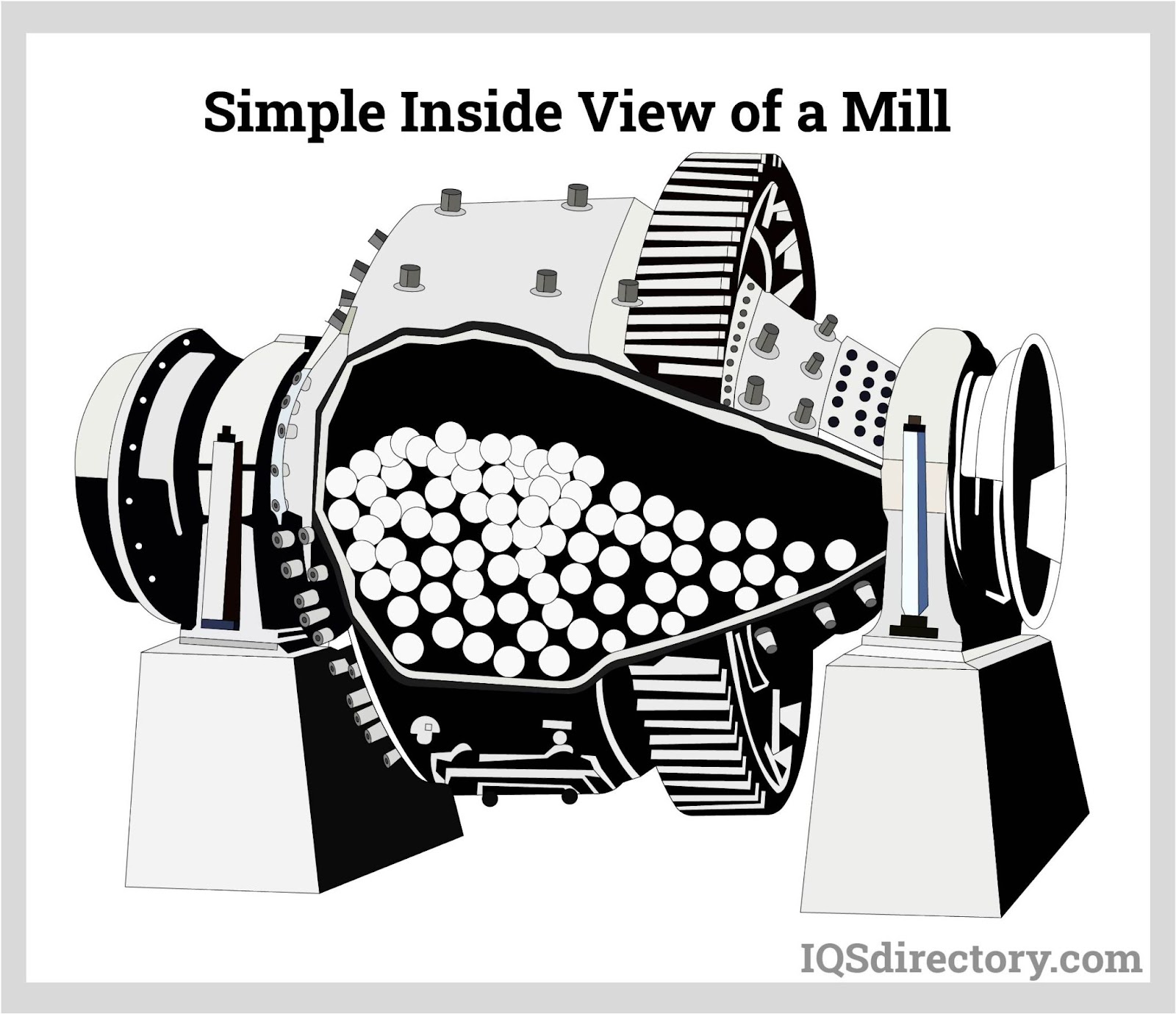

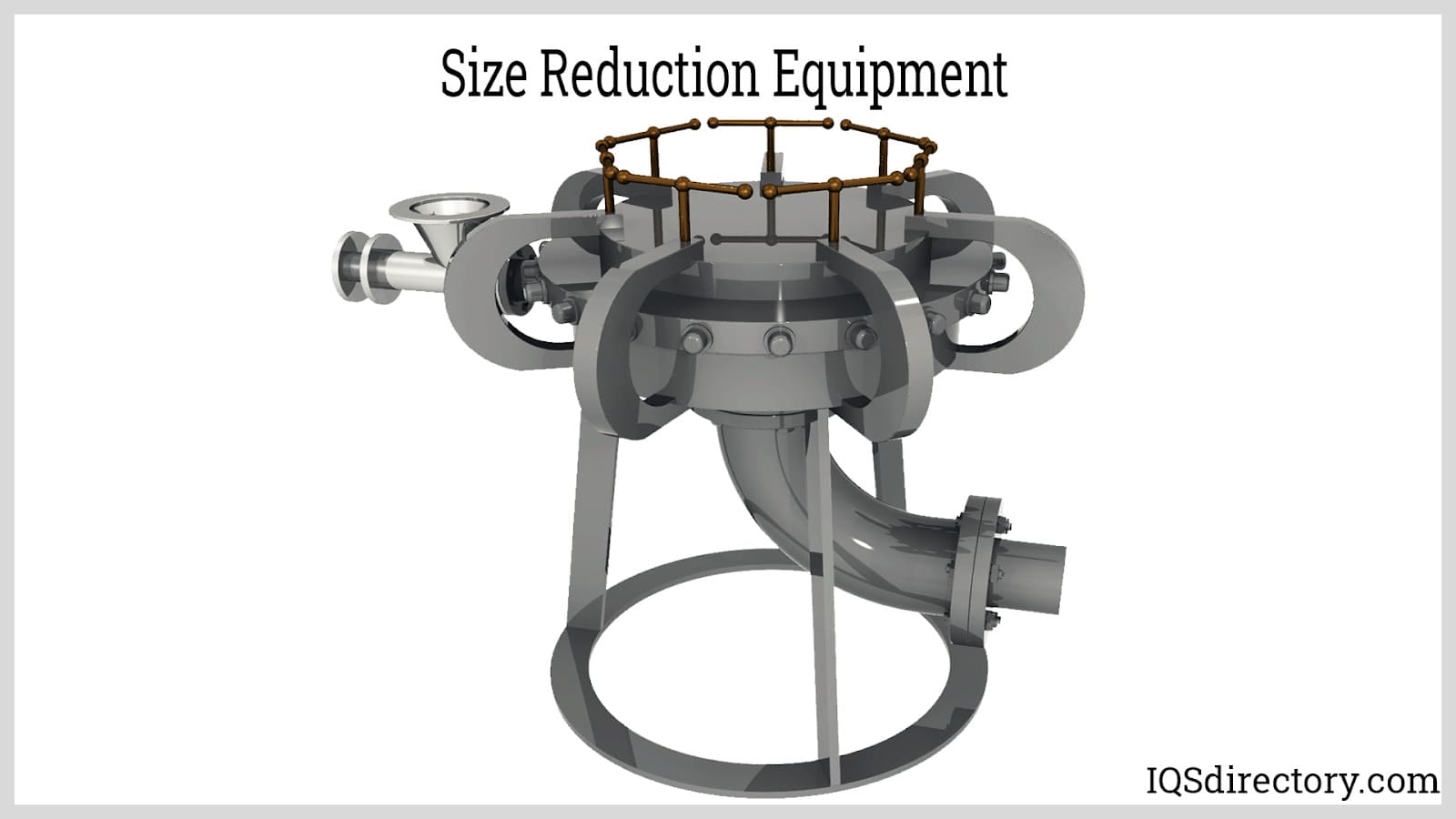

Grinders can be classified by a number of different factors based on how the grinder is powered as well as what materials are being processed. Different types of grinding mills include windmill, water mill, stamp mill, roller mill, oil mill, hammer mill, pellet mill, conical mill and many more. The ball mill is generally the most common type of grinder that converts large solid materials into powder. This type of grinder utilizes a cylindrical container that rotates and the container is filled with the material and a grinding medium such as stainless steel balls or ceramic balls. Read More...

Granutech-Saturn Systems

Turn to Granutech Saturn Systems where we can provide you with outstanding size reduction machinery such as grinders. We have a wide range of experience in a multitude of industries and our grinders can process 10 tons of scrap in an hour. Our staff can answer any of your questions and we cater our services to your needs. These uncompromising products are extremely reliable and we strive to bring quality grinders at a very affordable price. Just let us know your application and we can help select a product that will meet your needs. Our company has manufacturing experience dating back to 1968 and we have created some of the best innovations in our industry. We are your source for all of your grinder and shredding needs.

Grand Prairie, TX | 877-582-7800

Request for Quote

More Grinder Manufacturers

Disc Mills are grinders that are equipped with opposing discs that pulverize the materials as it is fed into the machine. Hammer mills have steel barrel with a number of hammers that are mounted to the shaft. The barrel will spin at a high rate which then crushes the material that is placed in the hammers path. Hammer mills also have a feature that allows the operator to adjust the screen size of the grinder which changes the size of the finished product.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services