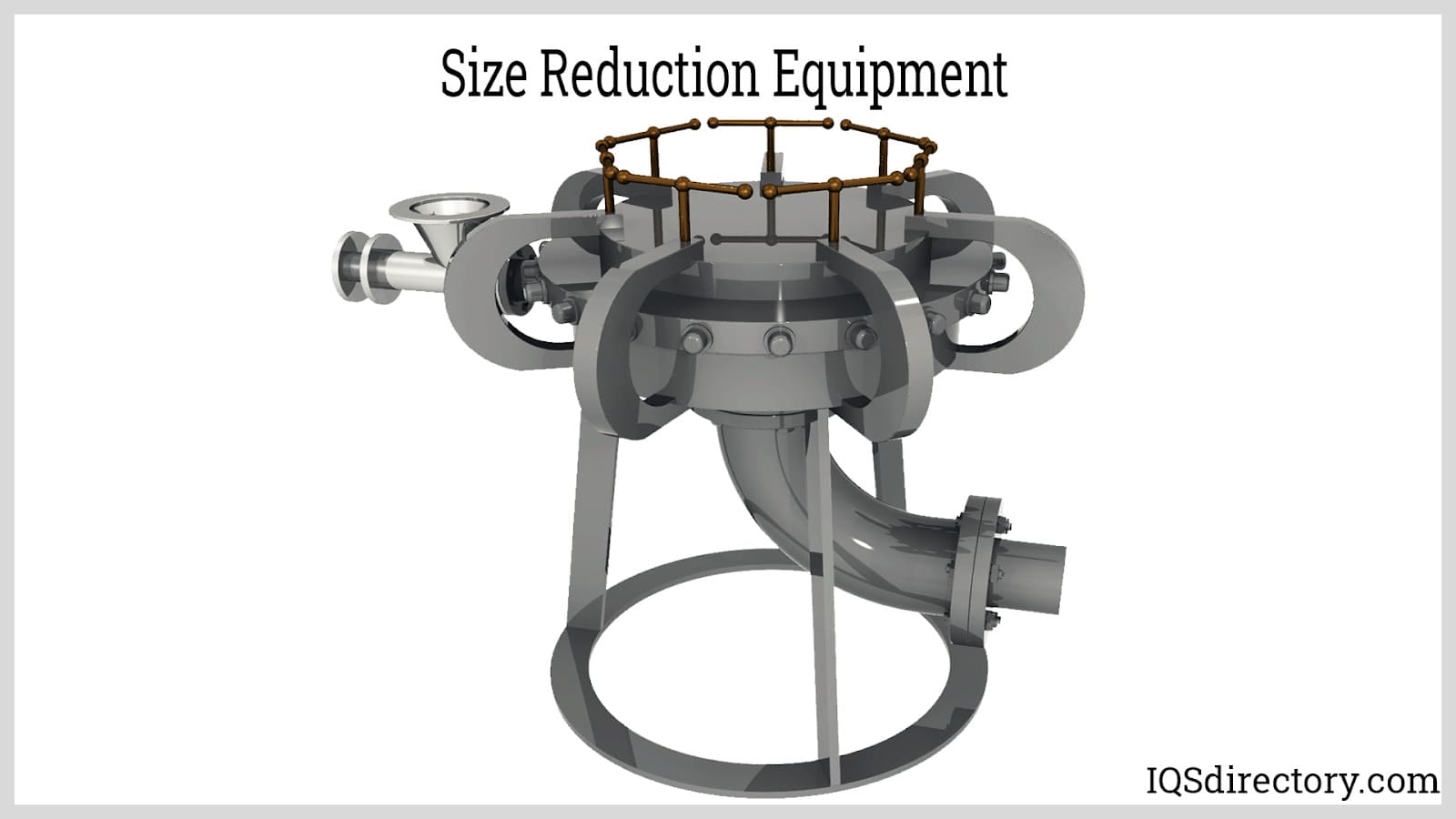

Size reduction equipment is used in a wide range of industries to break down large, bulky materials into smaller, more manageable pieces. This process is important for a variety of reasons, including improving product quality, increasing efficiency, and reducing waste. Read More…

Here at Granutech-Saturn Systems we manufacture high performance equipment which can handle the toughest projects. Our Saturn Hammermills are engineered to meet the specific requirements of a variety of applications.

SSI Shredding Systems, Inc. is ready to suit your shredding, compacting and pulverizing needs. We have multiple reducers to choose from to meet your pulverizing requirements with ease.

At Williams Patent Crusher & Pulverizer Co., we are industry leaders in the design and manufacture of high-performance pulverizers that set the standard for reliability, efficiency, and innovation. Since our establishment, we have remained committed to creating cutting-edge solutions that meet the diverse and demanding needs of industries such as mining, power generation, recycling, and more.

Eriez designs and manufactures pulverizers as well as a wide variety of other size reduction equipment. Our pulverizers can crush coal, chemicals, spices, bricks, soil, and more. We have developed solutions for the food, chemical, mining, and many other industries. If you need to separate your products or materials efficiently and quickly, call Eriez today!

Crush, grind, granulate, shred, pulverize, de-lump - Whatever material processing you need, TerraSource Global has the equipment you`ve been looking for. Since we first opened our doors, TerraSource Global has provided pulverizers, wood grinders, feed & grain mills, lumpbreakers and custom products to a number of industries. Manufacturing expertise defines our business. Call today!

More Size Reduction Equipment Manufacturers

In this article, we will discuss factors to consider when purchasing size reduction equipment, maintenance and troubleshooting tips for size reduction equipment, safety considerations for size reduction equipment, as well as some environmental considerations regarding size reduction equipment. We end this article by exploring emerging technologies and techniques for optimizing size reduction equipment.

Factors to Consider When Selecting Size Reduction Equipment

When selecting size reduction equipment, several factors must be considered to ensure optimal performance. These factors include the type of material being processed, the desired particle size, throughput requirements, and cost considerations. The material being processed must be considered because it can impact the type of equipment used, as well as the overall efficiency of the process. The desired particle size is also essential because it can impact the quality of the final product, while throughput requirements are critical for ensuring that the process can keep up with production demands. Cost considerations are also essential since size reduction equipment can vary widely in price.

Maintenance and Troubleshooting Tips for Size Reduction Equipment

To optimize the performance of size reduction equipment, regular maintenance and troubleshooting are essential. Here are some more details on maintenance and troubleshooting tips for size reduction equipment:

Maintenance Tips for Size Reduction Equipment

Keep the Equipment Clean

Regular cleaning of size reduction equipment is important to prevent blockages and ensure proper operation. Use appropriate cleaning agents and follow manufacturer's instructions for cleaning.

Lubrication

Proper lubrication can reduce wear and tear of the equipment and prolong its life. Follow manufacturer's guidelines for the type and frequency of lubrication.

Regular Inspection

Regular inspection of size reduction equipment can identify potential problems before they become major issues. Check for signs of wear and tear, loose bolts, and other issues that may impact performance.

Replace Worn Parts

Worn parts can significantly impact the performance of size reduction equipment. Replace worn parts as soon as possible to avoid further damage to the equipment.

Document Maintenance

Keep a record of all maintenance performed on size reduction equipment, including dates, parts replaced, and any issues identified. This record can help identify trends and provide insights into when equipment may need to be replaced.

Troubleshooting Tips for Size Reduction Equipment

Check for Blockages

Blockages are a common issue in size reduction equipment. Check for blockages in the equipment, including hoppers, feeders, and chutes. Clear blockages as soon as possible to avoid further damage to the equipment.

Check for Wear and Tear

Worn parts can significantly impact the performance of size reduction equipment. Check for signs of wear and tear, including loose bolts, broken parts, and damaged screens.

Adjust Settings

If the particle size is not meeting requirements, adjust the settings on the equipment, such as the speed or gap between blades.

Check for Unusual Noises or Vibrations

Unusual noises or vibrations can be a sign of issues with size reduction equipment. Shut down the equipment immediately and investigate the source of the problem.

Follow Manufacturers’ Instructions

Always follow the manufacturer's instructions for troubleshooting and maintenance of size reduction equipment. Failure to do so can result in damage to the equipment and potential safety hazards.

By following these maintenance and troubleshooting tips, operators can optimize the performance of size reduction equipment, minimize downtime, and extend the life of the equipment.

Safety Considerations for Size Reduction Equipment

Safety is paramount when working with size reduction equipment. Operators must receive proper training on how to operate the equipment safely, as well as the use of protective equipment, such as gloves, goggles, and earplugs. Proper operating procedures, such as locking out equipment before maintenance, must also be followed to minimize the risk of accidents or injuries.

Environmental Considerations for Size Reduction Equipment

Finally, environmental considerations must be taken into account when working with size reduction equipment. Strategies for reducing waste and energy consumption, such as recycling and the use of renewable energy sources, can help to minimize the environmental impact of size reduction processes. Additionally, equipment manufacturers are developing more environmentally friendly designs that use less energy and produce less waste.

Emerging Technologies and Techniques for Size Reduction

New technologies and techniques are emerging that are changing the landscape of size reduction equipment. For example, the use of advanced sensors and AI-based algorithms can help to optimize processes and reduce waste. The use of laser or ultrasonic methods is also gaining popularity in some industries, providing more precise and efficient size reduction processes.

Choosing the Correct Size Reduction Equipment Manufacturer

To ensure you have the most positive outcome when purchasing size reduction equipment from a size reduction equipment manufacturer, it is important to compare several companies using our directory of size reduction equipment manufacturers. Each size reduction equipment manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each size reduction equipment business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple size reduction equipment companies with the same form.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services