Ranging from very hard stones to soft minerals, stone can include slag, limestone, quartz, granite, iron ore, sandstone, copper ore, marble, cement and more. Since stone crushers can be used on such a wide range of materials, they can be utilized in a variety of applications in industries such as mining, for the crushing of mined and quarried stone; metallurgy, for the crushing of large stone into smaller stone that can be used in the process of working metal into parts and components; chemistry, to crush stone that can be used to process a variety of chemicals; construction, for the crushing of stone rubble that was previously used as building materials; and demolition, to crush debris left behind by the demolition of buildings, roadways, bridges, canals and various other structures. Read More…

Here at Granutech-Saturn Systems we manufacture high performance equipment which can handle the toughest projects. Our Saturn Hammermills are engineered to meet the specific requirements of a variety of applications.

At Williams Patent Crusher & Pulverizer Co., we are industry leaders in the design and manufacture of high-performance pulverizers that set the standard for reliability, efficiency, and innovation. Since our establishment, we have remained committed to creating cutting-edge solutions that meet the diverse and demanding needs of industries such as mining, power generation, recycling, and more.

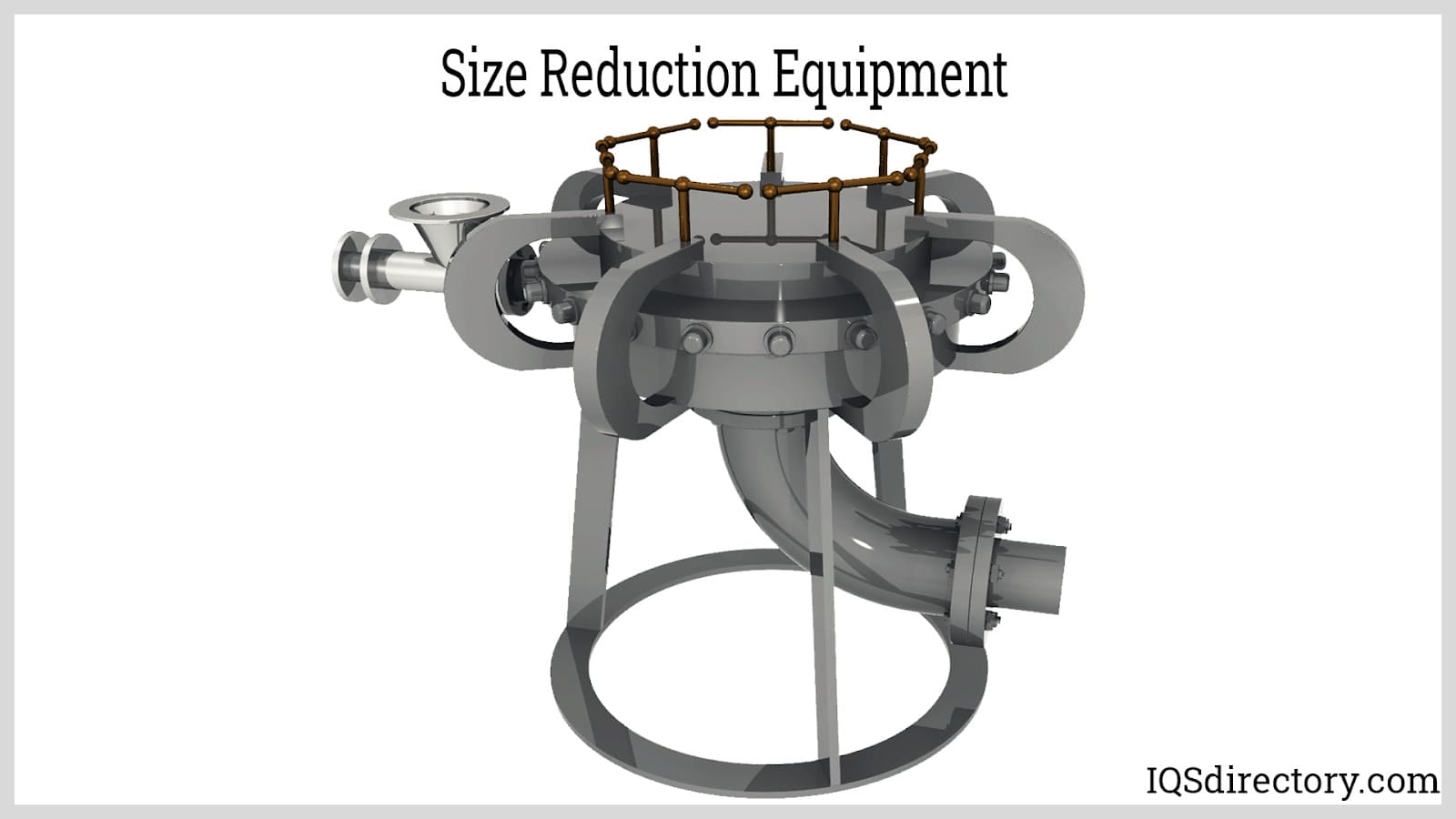

We are a trusted partner in delivering innovative size reduction solutions, and at DP Pulverizers Americas Inc., we have built our reputation on precision engineering, consistent quality, and a commitment to advancing material processing technology. Our expertise lies in designing and manufacturing size reduction equipment that meets the demanding needs of industries requiring efficient and...

More Stone Crusher Manufacturers

There are a few different types of crushers that are used to crush stone, including jaw crushers, cone crushers, hammer crushers and impact crushers. Using compression, jaw crushers feature two "jaw-like" surfaces. Referred to as jaws, jaw crushers have a fixed jaw and a mobile jaw. The mobile jaw enables crushing by exerting force on the stone and forcing it against the fixed jaw.

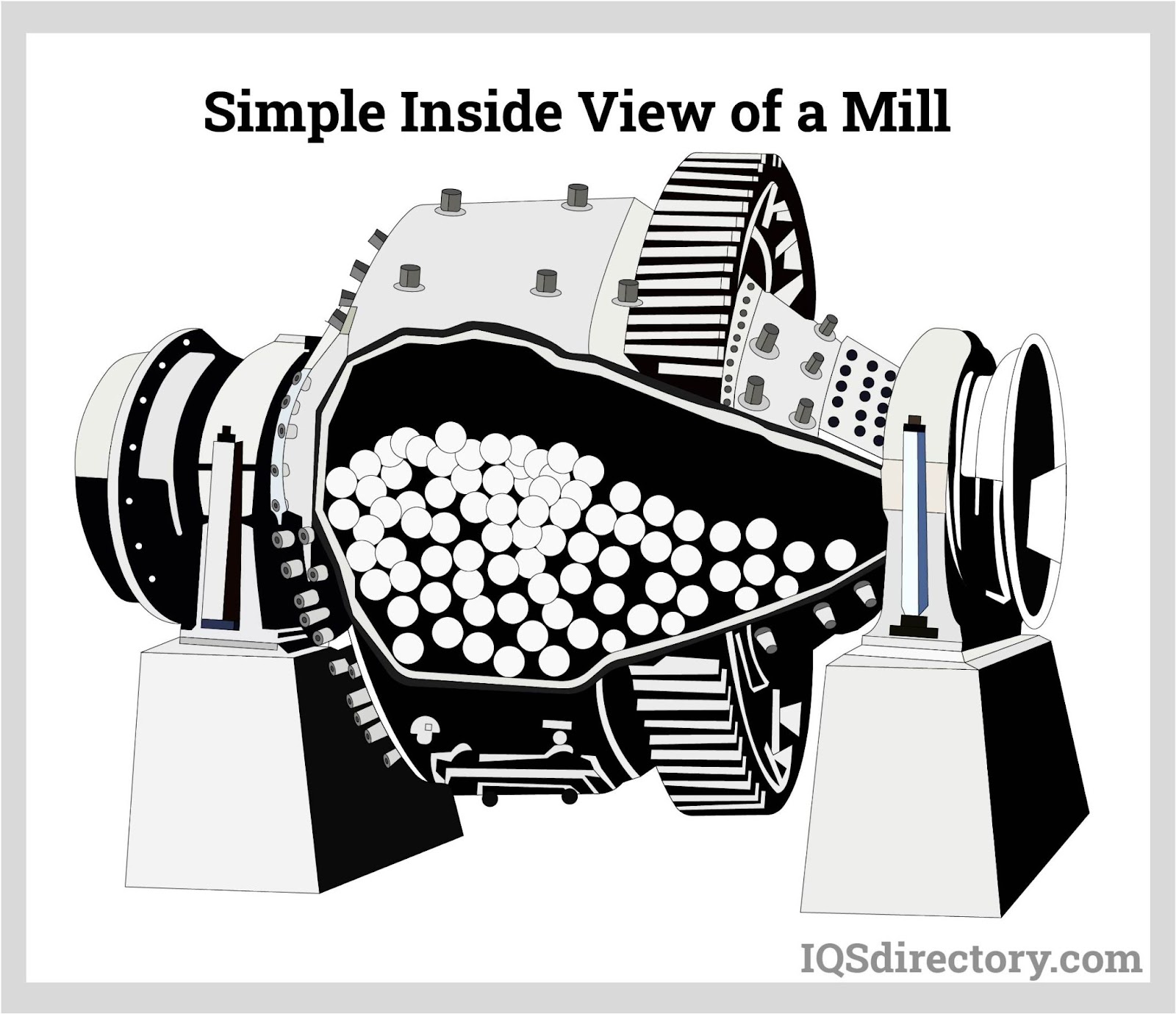

Also using compression, cone crushers are conically-shaped and provide crushing by squeezing the stone between a gyrating spindle powered by an eccentric arrangement and an enclosing concave hopper. Both parts are covered by wear-resistant materials to protect them from the broken bits of stone. Most often used as a secondary crusher, hammer crushers feature swinging arms on a revolving shaft that crush the stone against the crusher's iron cage; once crushed, a screen at the bottom of the crusher allows fine stone pieces to exit.

Also referred to as a hammermill, another type of hammer crusher is a reversible hammer mill that can run alternately in either direction. Lastly, instead of using compression, impact crushers break apart stone by means of impaction, which refers to a collision-wrought force. Impact crushers come in two main types: horizontal shaft impactors (HSI) and vertical shaft impactors (VSI).

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services